-

The performance and longevity of an engine depend heavily on the integrity of its components. One su...

READ MORE -

In modern automotive systems, nbr wear resistance auto parts oil seal play a crucial role in maintai...

READ MORE -

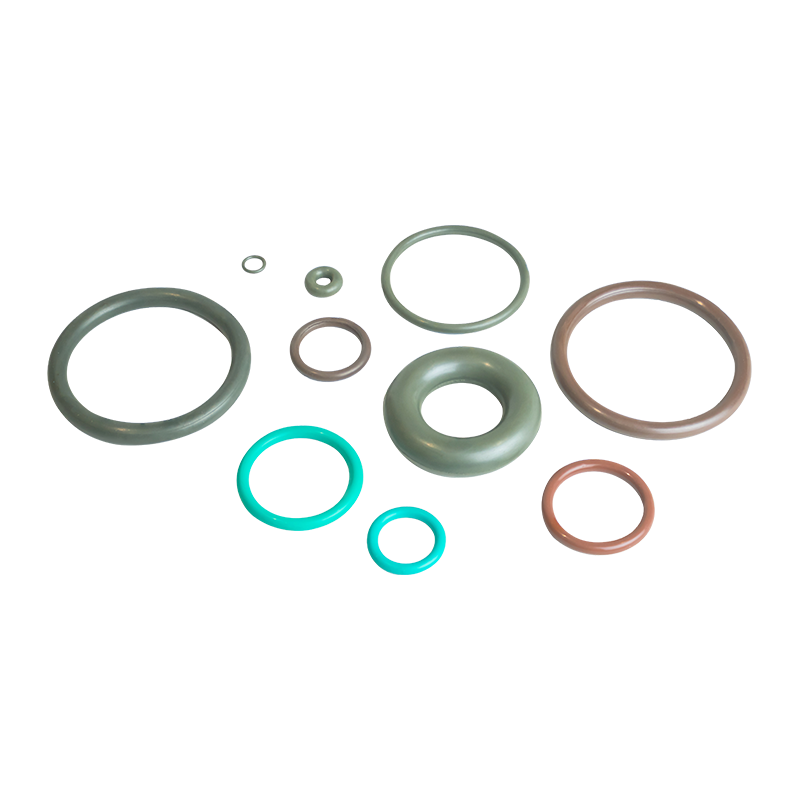

Hydrogenated nitrile (HNBR) O-Ring Seal Kits are widely used in industrial applications due to their...

READ MORE -

The evolution of FAWDE Engine Parts PTFE Oil Seal reflects the ongoing demand for higher efficiency,...

READ MORE -

Ensuring that a nbr mechanical seal rubber o-ring kit fits your equipment correctly is a critical st...

READ MORE

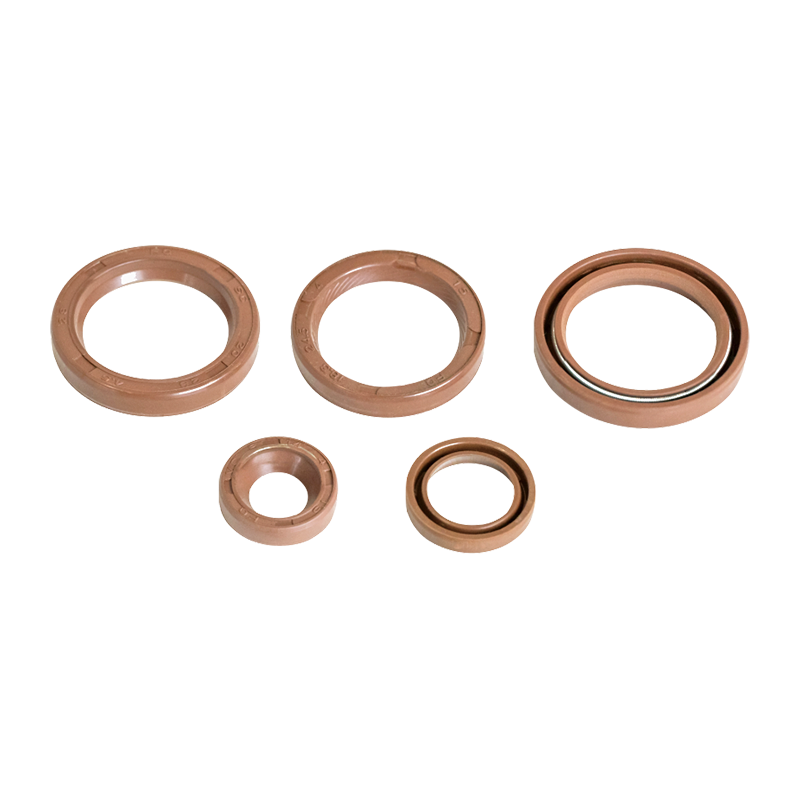

Does the mold design of the TB type automotive parts oil seal kit take into account the product's use environment and stress distribution? How to ensure that the mold design meets the product's performance requirements?

1. In-depth consideration of the environment and stress distribution in mold design

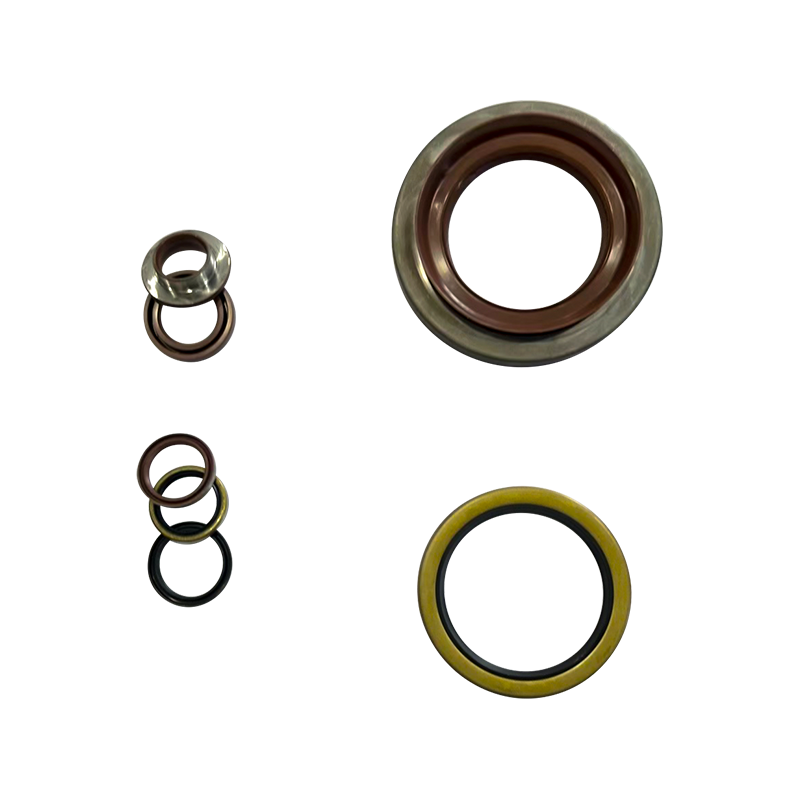

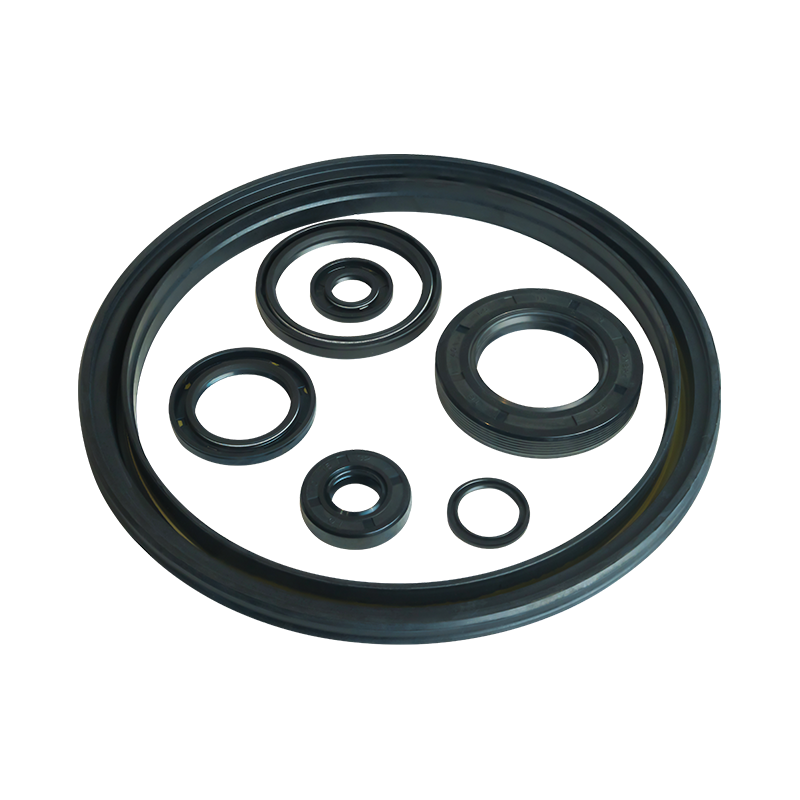

TB type oil seal kits are mainly used in key parts of automobiles such as engines, gearboxes, and wheels. The working environment of these parts is extremely harsh. Not only do they face the challenges of high temperature, high pressure, and high-speed rotation, but they also need to withstand the erosion of chemicals such as lubricants and coolants. Therefore, in the mold design stage, we first conducted a detailed analysis of the use environment, including but not limited to temperature range, pressure level, contact medium characteristics, etc., to ensure that the mold design can adapt to these extreme conditions and ensure the sealing and durability of the product during use.

Using advanced computer-aided engineering (CAE) technology, such as finite element analysis (FEA), the stress distribution of the TB type oil seal kit during use is simulated and predicted. Through precise modeling, the stress conditions of the main lip and the auxiliary lip under different working conditions are analyzed, especially the centrifugal force, thermal expansion stress, and lubricating oil pressure at high-speed rotation. The influence on the sealing interface. This step is crucial for optimizing mold structure, adjusting material thickness, designing reasonable reinforcement ribs, etc., aiming to reduce stress concentration and improve the fatigue strength and sealing performance of the product.

2. Strategies to ensure that mold design meets product performance requirements

Relying on the company's advanced intelligent mold library and fully automatic auxiliary machine mixing system, we are able to achieve high-precision processing and rapid iteration of molds. The mold is made of high-quality alloy materials, and undergoes precise CNC processing and heat treatment processes to ensure that the mold size is stable and wear-resistant. In addition, the application of the intelligent mold library realizes the rapid call and management of the mold, shortens the product development cycle, and improves production efficiency.

The TB type oil seal kit uses fluororubber as an elastic material. The choice of this material is based on its excellent oil resistance, high temperature resistance, and chemical corrosion resistance. We cooperate with many domestic universities and scientific research institutions to continuously optimize the formula of fluororubber through industry-university-research projects to improve its sealing effect and durability in extreme environments. In mold design, we fully consider the shrinkage and fluidity of fluororubber to ensure that the mold cavity design can perfectly match the material properties and avoid molding defects.

After the mold design is completed, it must undergo rigorous verification and testing. This includes mold trials, dimensional inspection of product samples, performance testing, and durability testing that simulates the actual use environment. The company's advanced testing equipment, such as analytical balances, electronic tensile testing machines, and aging test chambers, can comprehensively evaluate the physical and chemical properties, sealing performance, and performance retention rate of products after aging. Especially for TB-type oil seal kits, we will conduct special oil seal radial force testing, high-temperature creep stress relaxation testing, etc. to ensure that it can maintain a stable sealing effect in long-term use.

Based on customer feedback and test results, we have established a continuous improvement mechanism. Once deficiencies in mold design or product performance are found, the optimization process is immediately started, from design adjustments, material improvements to production process optimization, to form a closed-loop feedback system. This continuous iterative optimization ensures that the TB-type oil seal kit can continue to adapt to market changes and technological advances, and always remain at the forefront of the industry.

English

English русский

русский 中文简体

中文简体