-

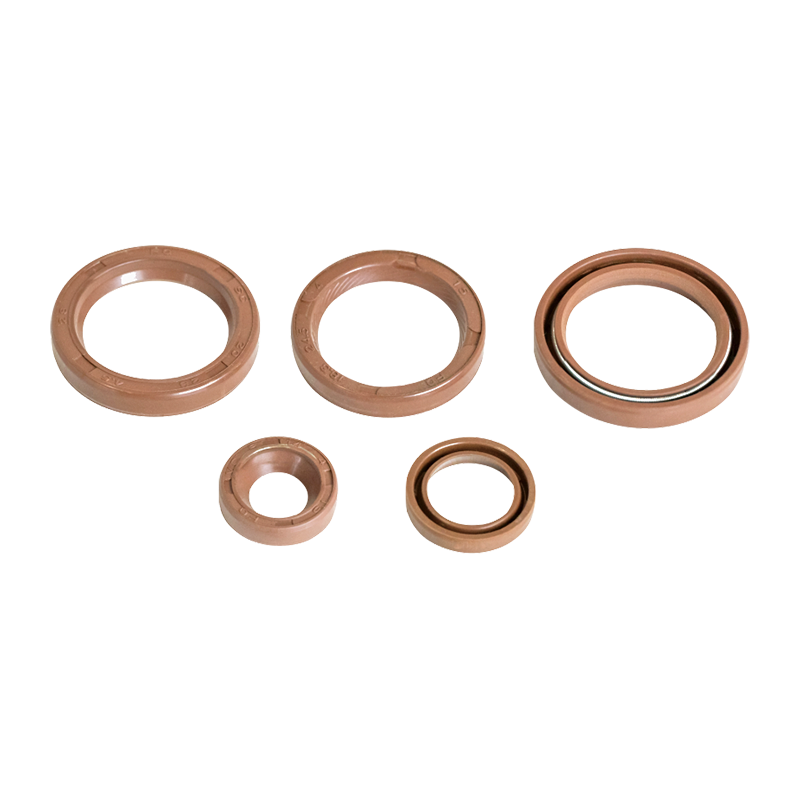

The performance and longevity of an engine depend heavily on the integrity of its components. One su...

READ MORE -

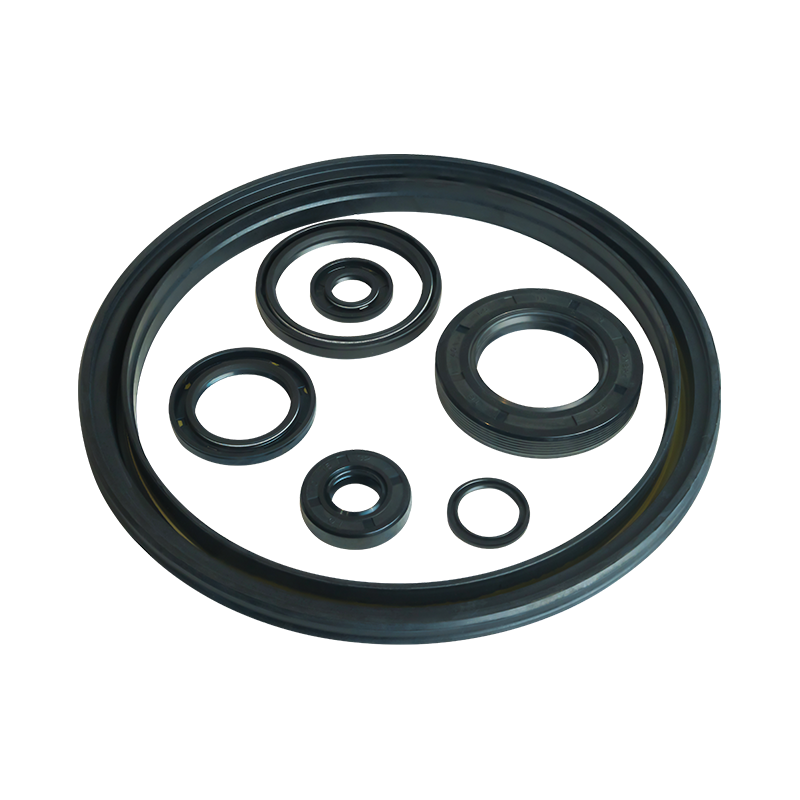

In modern automotive systems, nbr wear resistance auto parts oil seal play a crucial role in maintai...

READ MORE -

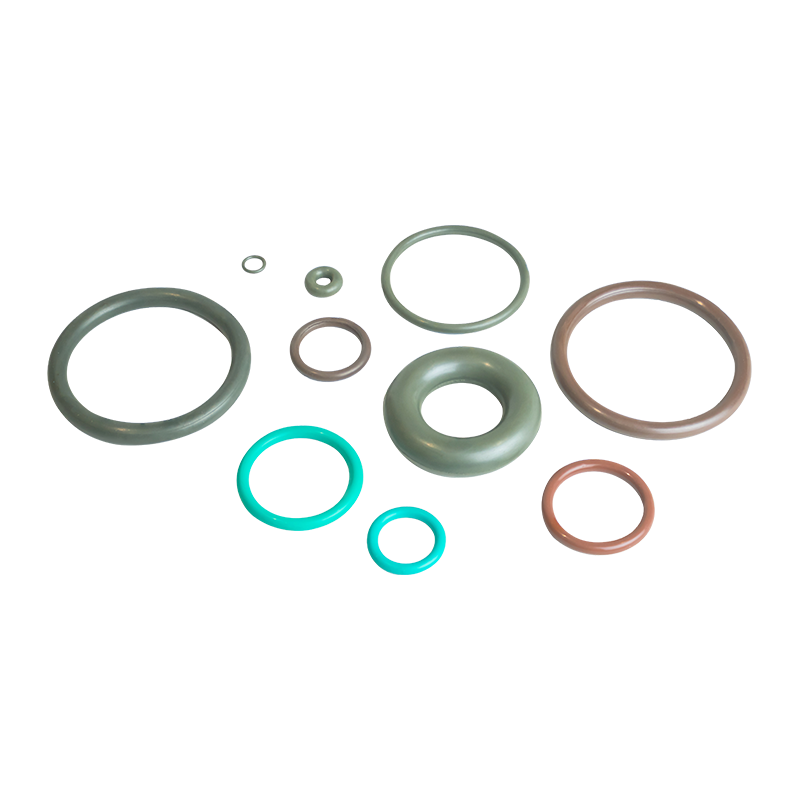

Hydrogenated nitrile (HNBR) O-Ring Seal Kits are widely used in industrial applications due to their...

READ MORE -

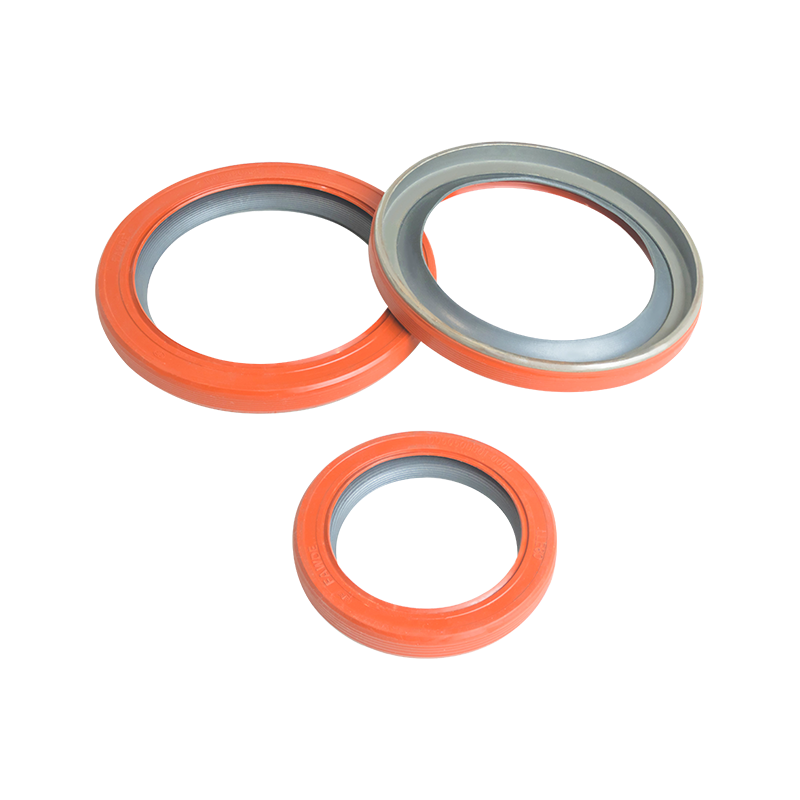

The evolution of FAWDE Engine Parts PTFE Oil Seal reflects the ongoing demand for higher efficiency,...

READ MORE -

Ensuring that a nbr mechanical seal rubber o-ring kit fits your equipment correctly is a critical st...

READ MORE

How to cool the PTFE oil seal of FAWDE engine accessories after molding? What precautions should be taken during the cooling process?

1. Cooling treatment method of PTFE oil seal after molding

Natural cooling method is the most basic cooling method, which is suitable for small or low-requirement PTFE oil seals. This method uses natural convection of air to dissipate heat without the need for additional equipment investment. However, the disadvantage of natural cooling is that the cooling speed is slow, which can easily lead to uneven distribution of internal stress of the product, affecting the dimensional accuracy and mechanical properties of the product. Therefore, for FAWDE engine accessories PTFE oil seals with high performance requirements, natural cooling method is usually not the first choice.

In order to improve cooling efficiency, the company adopts an advanced forced air cooling system. The system generates a strong airflow through a high-speed fan to accelerate the heat loss on the surface of the oil seal. The forced air cooling method not only shortens the cooling time, but also effectively reduces the generation of internal stress and ensures the dimensional stability and mechanical strength of the product. In addition, our air cooling system is equipped with an intelligent temperature control device, which can automatically adjust the wind speed and temperature according to the material and size of the oil seal to ensure the best cooling effect.

For large-sized or high-requirement PTFE oil seals, the company also introduced a water cooling method. The water cooling method uses the high thermal conductivity of water to quickly remove heat from the oil seal. To ensure uniform cooling, we designed a special water cooling mold to evenly spray cooling water on the surface of the oil seal through a circulating water pump. The water cooling method has an extremely fast cooling speed, which can significantly shorten the production cycle while ensuring the quality and performance of the product. However, it should be noted that the water temperature must be strictly controlled during the water cooling process to avoid the embrittlement of the oil seal material due to too low water temperature.

2. Precautions during the cooling process

Temperature control during the cooling process is the key to ensuring product quality. Whether it is air cooling or water cooling, the temperature of the cooling medium needs to be strictly controlled. If the temperature is too high, the cooling effect is not good; if the temperature is too low, it may cause physical or chemical changes in the oil seal material, affecting its performance. The company is equipped with an advanced temperature control system that can monitor and adjust the temperature of the cooling medium in real time to ensure that the cooling process is carried out within the optimal temperature range.

The cooling rate has an important influence on the internal stress distribution and dimensional accuracy of the oil seal. If the cooling rate is too fast, it may cause excessive internal stress, causing deformation or cracking; if the cooling rate is too slow, it may extend the production cycle and reduce production efficiency. Therefore, during the cooling process, we need to reasonably set the cooling speed according to the material, size and production requirements of the oil seal.

Cooling uniformity is an important factor in ensuring the quality of the oil seal. If the cooling is uneven, it may lead to large temperature differences in various parts of the oil seal, causing uneven distribution of thermal stress, thus affecting the dimensional accuracy and mechanical properties of the product. The company uses advanced cooling equipment and processes to ensure that the cooling medium can be in uniform and sufficient contact with the oil seal to achieve uniform cooling.

After cooling, the oil seal also needs to be processed, such as cleaning, drying and inspection. Cleaning can remove the cooling medium and impurities remaining in the cooling process to ensure the cleanliness of the product; drying can avoid residual moisture and prevent the oil seal from corrosion or performance degradation during use; inspection is an important link to ensure product quality. By testing indicators such as the size, mechanical properties and sealing performance of the oil seal, ensure that the product meets the design requirements.

3. Company's technical advantages and strengths

As an enterprise with a full set of advanced testing equipment and intelligent production workshops, we have significant advantages in the production and cooling treatment of PTFE oil seals. Our intelligent mold library and intelligent vulcanization workshop can ensure the precise control of the oil seal molding process; advanced testing equipment can conduct comprehensive and accurate testing of various performance indicators of oil seals. In addition, we have established close industry-university-research cooperation with many domestic universities and scientific research institutions, and continuously introduced new technologies and processes to improve the technical content and market competitiveness of our products.

English

English русский

русский 中文简体

中文简体