-

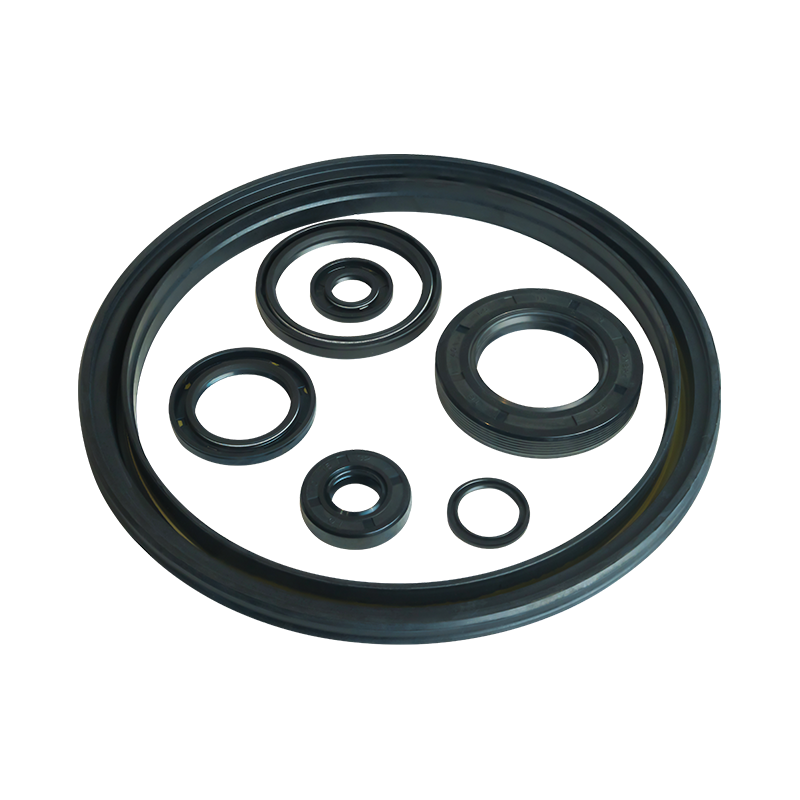

In modern automotive systems, nbr wear resistance auto parts oil seal play a crucial role in maintai...

READ MORE -

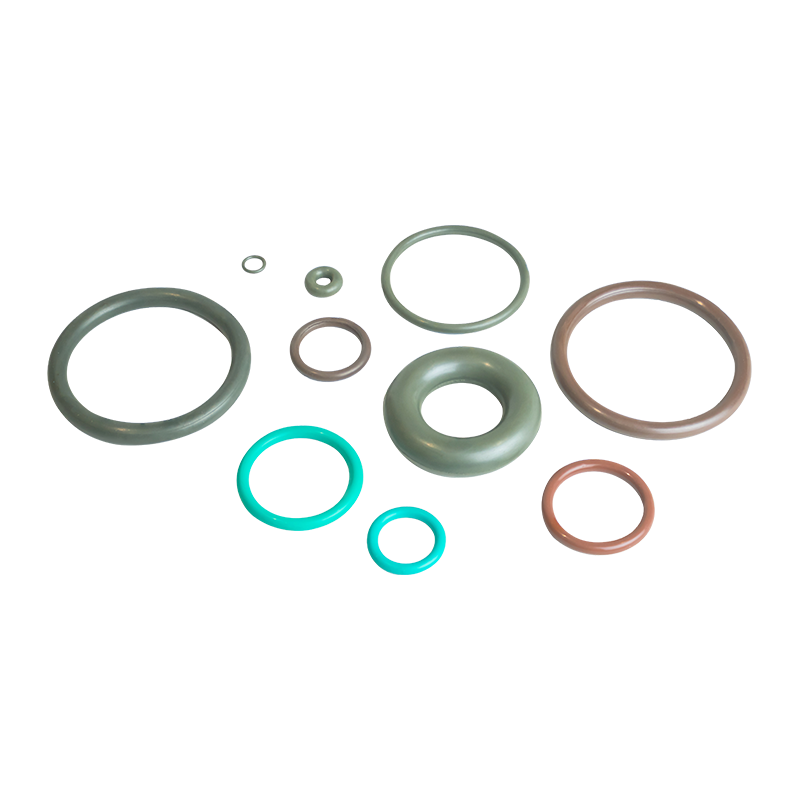

Hydrogenated nitrile (HNBR) O-Ring Seal Kits are widely used in industrial applications due to their...

READ MORE -

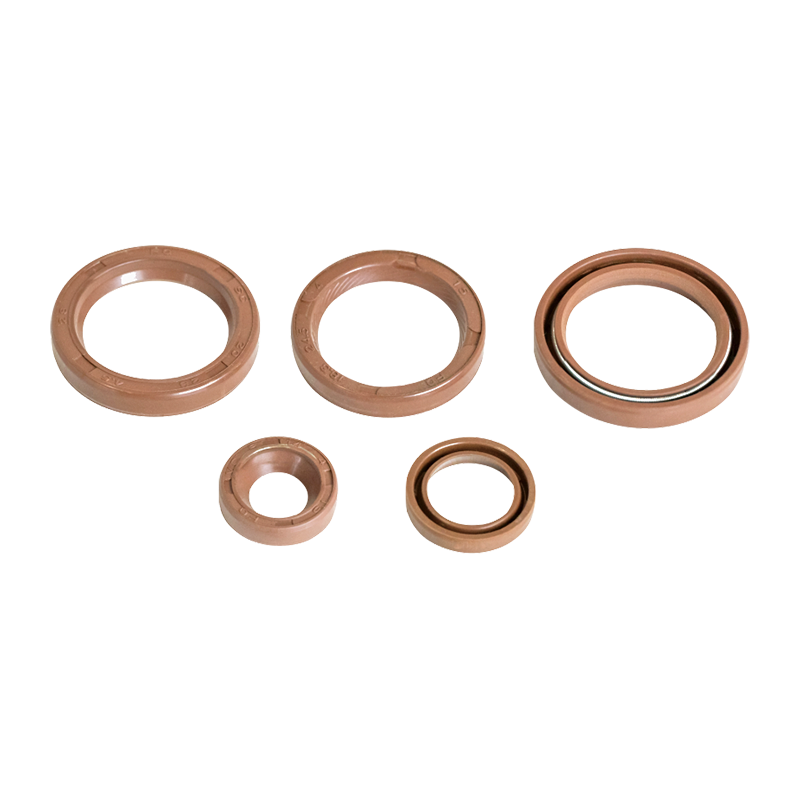

The evolution of FAWDE Engine Parts PTFE Oil Seal reflects the ongoing demand for higher efficiency,...

READ MORE -

Ensuring that a nbr mechanical seal rubber o-ring kit fits your equipment correctly is a critical st...

READ MORE -

Introduction: The Critical Role of Sealing in Engine Reliability In the world of machinery and engin...

READ MORE

How are the semi-finished products of the engine wear-resistant crankshaft oil seal kit manufactured? Is precision preforming technology used?

The performance of the engine wear-resistant crankshaft oil seal kit depends largely on the selected materials. The company uses high-quality rubber raw materials, which are strictly screened to ensure excellent wear resistance, oil resistance, high temperature resistance and good elastic recovery. After the raw materials enter the factory, they are first accurately weighed by the high-precision analytical balance equipped in the company's intelligent vulcanization workshop to ensure the consistency of each batch of materials. In addition, the company also has equipment such as electronic tensile testing machines and aging test chambers to test the mechanical properties and aging resistance of raw materials to further ensure that the quality of the materials meets high standards.

In the manufacturing process of the semi-finished products of the engine wear-resistant crankshaft oil seal kit, precision preforming technology is a key technology. This technology fully considers the geometry of the oil seal, the precise size of the sealing lip, and the shrinkage rate of the material during the vulcanization process in the mold design stage, so as to ensure that the shape and size requirements close to the final product can be achieved in the molding stage.

Application of intelligent mold library: The company is equipped with an intelligent mold library, which stores precision molds designed for different models of engine crankshaft oil seals. These molds are designed and manufactured using advanced CAD/CAM technology to ensure high precision and long life of the molds. Before the mold is selected and used, the size will be checked by a projector (two-dimensional) to ensure that the precision of the mold meets the production requirements.

Fully automatic upper auxiliary machine mixing system: After the raw materials are accurately proportioned, they enter the fully automatic upper auxiliary machine mixing system. The system can strictly control the mixing temperature, time and pressure to ensure the uniformity and stability of the rubber material. The mixed material is directly sent to the molding machine through an intelligent conveying system, which reduces manual intervention and improves production efficiency and product quality stability.

Precision preforming process: After the mold is installed, the mixed rubber material is injected into the mold. At this time, the molding machine will be precisely controlled according to the preset molding parameters (such as temperature, pressure and time). Due to the use of precision preforming technology, the precise design of the mold and the precise control of the molding machine are combined, which significantly improves the dimensional accuracy and shape stability of the semi-finished product.

After the precision preforming process is completed, the semi-finished product obtained needs to undergo strict quality inspection and screening. The company uses a series of advanced testing equipment, including but not limited to micro melting point meter, rubber and plastic density meter, hardness tester and thickness gauge, etc., to conduct comprehensive testing on the physical properties, dimensional accuracy and appearance quality of semi-finished products.

Physical performance test: The tensile strength, elongation at break and other mechanical properties of semi-finished products are tested by electronic tensile testing machine; the hardness is tested by hardness tester to ensure that it meets the design requirements.

Dimensional accuracy inspection: The dimensions of semi-finished products are accurately measured using projectors (two-dimensional) and Phoenix dimensional detection equipment to ensure consistency with the requirements of the drawings.

Appearance quality inspection: Through visual inspection and flaw detector inspection, it is ensured that there are no defects such as cracks, bubbles, impurities, etc. on the surface of semi-finished products.

In the semi-finished product manufacturing process of engine wear-resistant crankshaft oil seal kits, the company has fully utilized its advantages in technology research and development and equipment advancement. The company has established a close industry-university-research cooperation relationship with many domestic universities and scientific research institutions, and continuously introduced new technologies, new materials and new processes to enhance the technical content and added value of products. At the same time, the company has established a complete quality assurance system. From raw material procurement, production process control to finished product inspection, every link is strictly carried out in accordance with ISO quality management system standards.

Especially in the field of precision preforming technology, the company not only has advanced mold design and manufacturing capabilities, but also improves the automation level and precision control capabilities of the molding process through continuous research and development and innovation. This not only improves production efficiency, but also significantly improves product quality and stability.

English

English русский

русский 中文简体

中文简体