-

The bosch 26 electric hammer parts rubber seal ring is a critical component in maintaining the effic...

READ MORE -

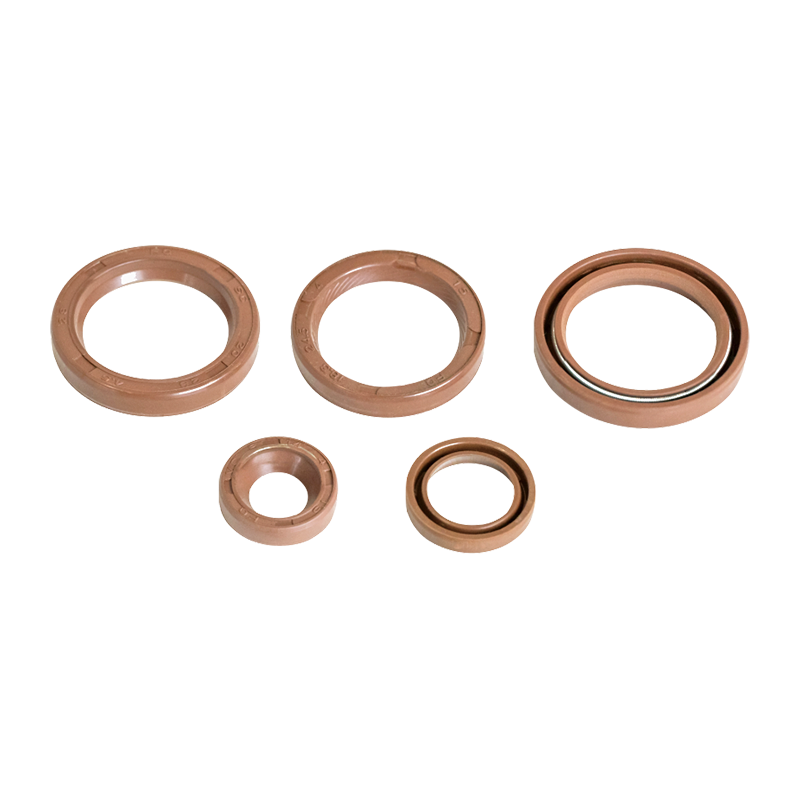

A TB Type Auto Parts Oil Seal Kit plays a crucial role in maintaining the proper functioning of auto...

READ MORE -

The performance and longevity of an engine depend heavily on the integrity of its components. One su...

READ MORE -

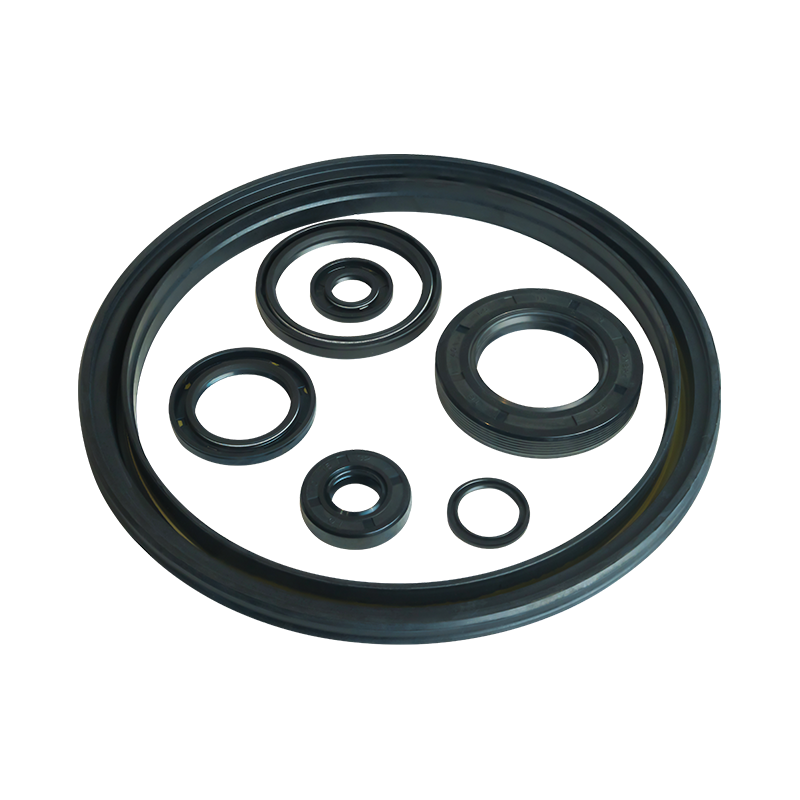

In modern automotive systems, nbr wear resistance auto parts oil seal play a crucial role in maintai...

READ MORE -

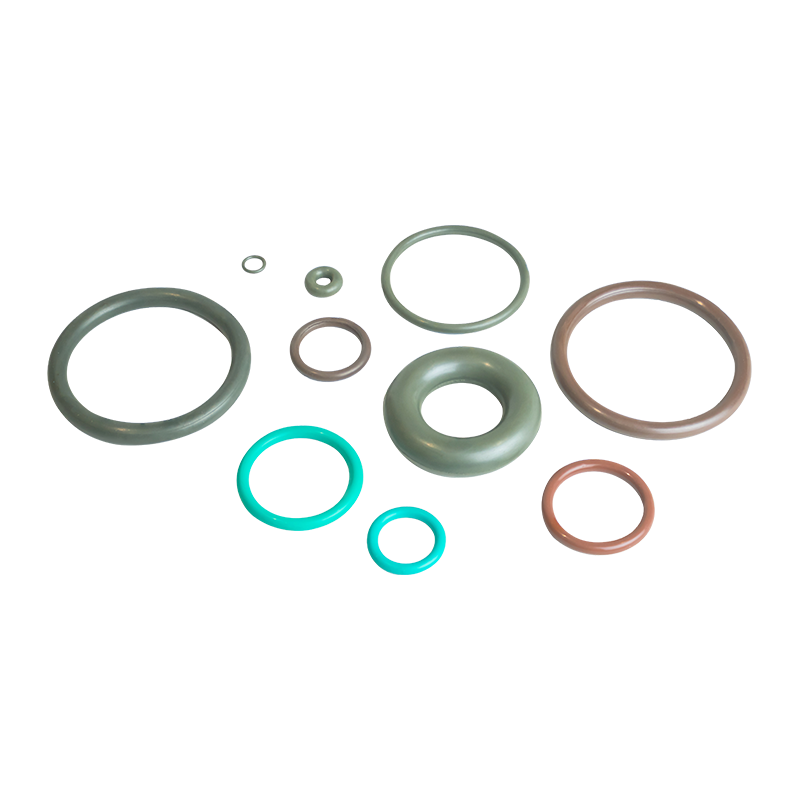

Hydrogenated nitrile (HNBR) O-Ring Seal Kits are widely used in industrial applications due to their...

READ MORE

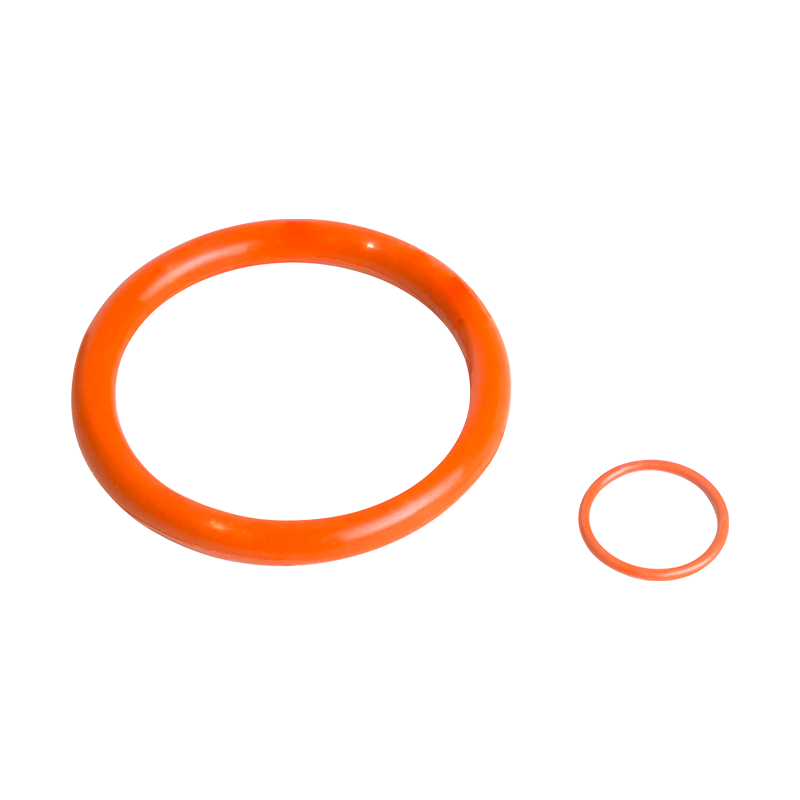

During the molding process of the red silicone O-ring seal, how to control parameters such as temperature, pressure and time to ensure the quality and performance of the product? Is there a special monitoring and adjustment mechanism?

Temperature is a key factor affecting the fluidity and curing speed of silicone materials. During the molding process of the red silicone O-ring, we need to accurately control the temperature of the mold and the vulcanization workshop to ensure that the silicone material can be evenly heated and cured smoothly.

Intelligent vulcanization workshop: We are equipped with an intelligent vulcanization workshop, which uses an advanced temperature control system to monitor and adjust the temperature in real time. Through the preset temperature control program, the temperature in the workshop can be accurately controlled within ±1℃, ensuring that the silicone material is evenly heated during the vulcanization process and avoiding the impact of temperature fluctuations on product performance.

Mold temperature control: The temperature of the mold is also crucial. We use an advanced mold heating and cooling system that can quickly heat the mold to the required vulcanization temperature and quickly cool it after the vulcanization is completed. This system not only improves production efficiency, but also ensures the accuracy and stability of the mold temperature.

Material preheating: Before injecting the silicone material into the mold, we will also preheat it. This step helps the material reach the vulcanization temperature faster and more evenly in the mold, further improving the quality and performance of the product.

Pressure is a key factor affecting the density and dimensional accuracy of silicone O-rings. During the molding process, we need to accurately control the injection pressure and vulcanization pressure to ensure that the silicone material can fully fill the mold and form a good sealing structure.

Fully automatic upper auxiliary machine mixing system: Our fully automatic upper auxiliary machine mixing system can accurately control the proportion and mixing process of the silicone material to ensure the uniformity and stability of the material. This system is also equipped with a precise injection device that can accurately control the injection pressure and injection speed to ensure that the silicone material can be smoothly injected into the mold and fill every corner.

Vulcanization pressure control: During the vulcanization process, we use an advanced pressure control system that can monitor and adjust the vulcanization pressure in real time. Through the preset pressure program, we can ensure that the vulcanization pressure remains constant throughout the vulcanization process, thereby avoiding the impact of pressure fluctuations on the dimensional accuracy and density of the product.

Mold design: The design of the mold is also crucial to pressure control. Our mold uses advanced flow channel design and exhaust system to ensure that the silicone material flows smoothly and exhausts bubbles during the injection process. This design not only improves the molding quality of the product, but also reduces the scrap rate.

Time is a key factor affecting the curing degree and performance of silicone O-rings. During the molding process, we need to accurately control the vulcanization time to ensure that the silicone material can fully cure and form good physical properties.

Vulcanization time program: We have developed a precise vulcanization time program based on the characteristics of the silicone material and the design of the mold. Through the preset vulcanization time, we can ensure that the silicone material reaches the optimal degree of curing during the vulcanization process, thereby avoiding the impact of insufficient or excessive curing on product performance.

Real-time monitoring and adjustment: During the vulcanization process, our intelligent vulcanization workshop will monitor parameters such as vulcanization time and temperature in real time. Once an abnormality is found, the system will immediately issue an alarm and automatically adjust the vulcanization parameters to ensure that the quality and performance of the product are not affected.

In order to ensure the quality and performance of the red silicone O-ring seals during the molding process, we have also established a complete monitoring and adjustment mechanism.

Full process quality inspection: After each process, we will conduct strict inspections on the products. For the final finished product, we will conduct a full inspection according to customer requirements and international standards to ensure that each product meets quality standards.

Advanced testing equipment: We have the most advanced and complete testing equipment in the industry, such as analytical balances, electronic tensile testing machines, aging test chambers, etc. These equipment can accurately measure the physical and chemical properties of the product, thereby ensuring that the quality and performance of the product meet customer requirements.

Industry-university-research cooperation: We have established close industry-university-research cooperation with many domestic universities and scientific research institutions, and continuously introduced new technologies and new equipment. Through continuous technological innovation and equipment upgrades, we can continuously improve the quality and performance level of our products.

English

English русский

русский 中文简体

中文简体