-

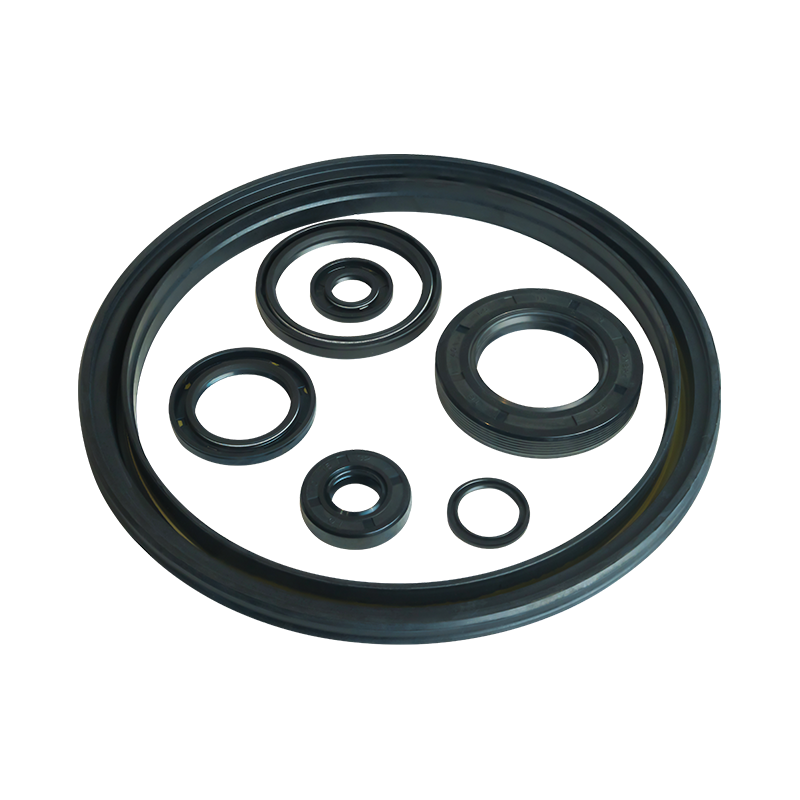

A TB Type Auto Parts Oil Seal Kit plays a crucial role in maintaining the proper functioning of auto...

READ MORE -

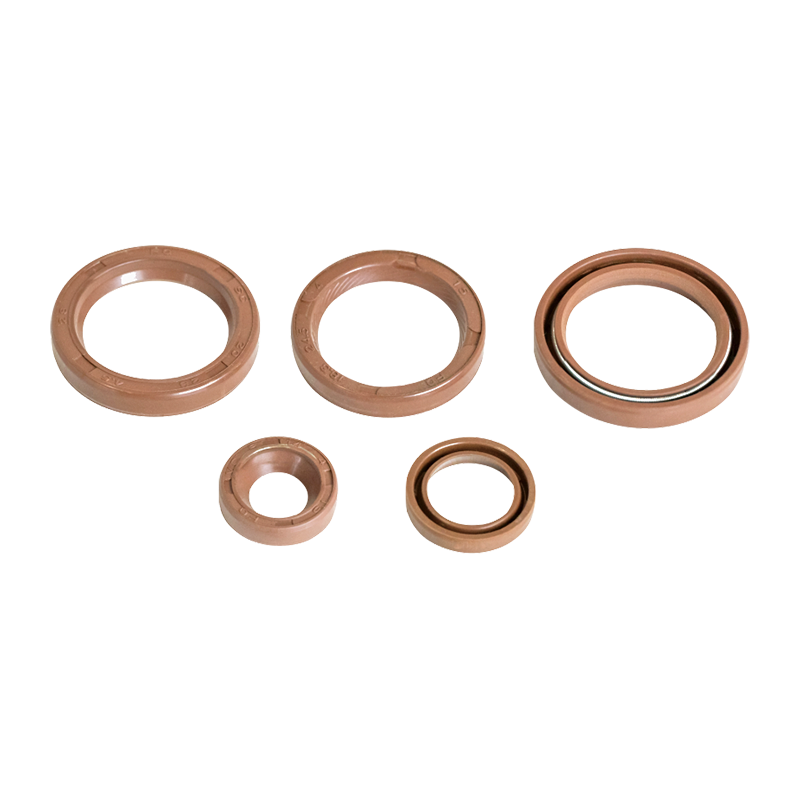

The performance and longevity of an engine depend heavily on the integrity of its components. One su...

READ MORE -

In modern automotive systems, nbr wear resistance auto parts oil seal play a crucial role in maintai...

READ MORE -

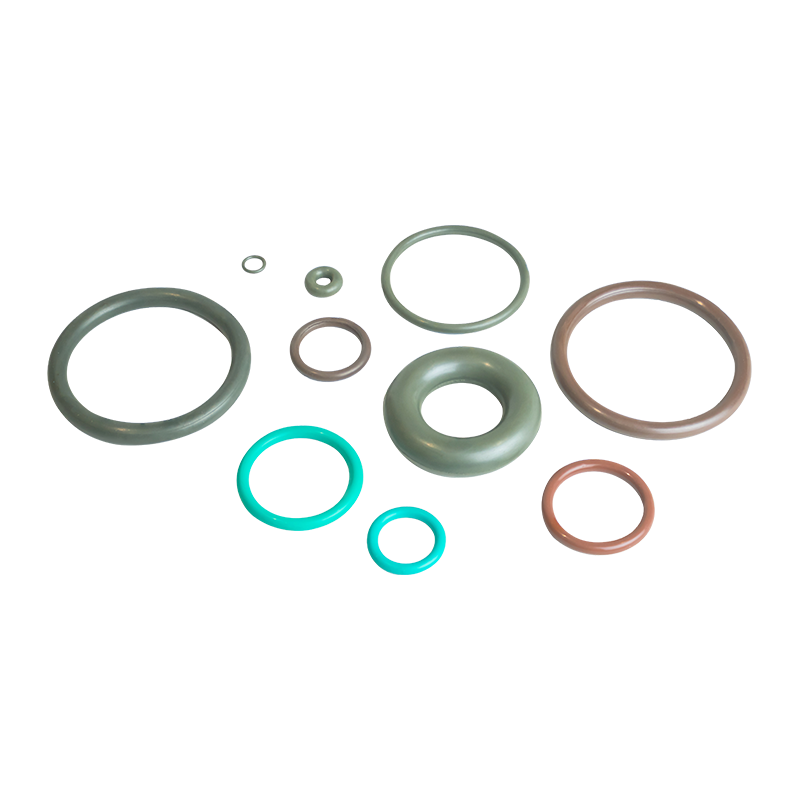

Hydrogenated nitrile (HNBR) O-Ring Seal Kits are widely used in industrial applications due to their...

READ MORE -

The evolution of FAWDE Engine Parts PTFE Oil Seal reflects the ongoing demand for higher efficiency,...

READ MORE

What special testing equipment and means are used to test the performance of fluororubber FKM O-rings? Such as high temperature resistance, chemical corrosion resistance, etc.

1. Analytical balance:

As the basis for precision measurement, the analytical balance can accurately weigh the quality of fluororubber FKM O-ring samples and provide an accurate data basis for subsequent physical and chemical performance tests. Its high sensitivity and stability ensure the accuracy of the test results.

2. Electronic tensile testing machine:

This equipment is used to evaluate the tensile strength, elongation at break and other mechanical properties of fluororubber materials. It is a key means to verify whether the FKM O-ring can maintain structural integrity when under pressure. By simulating the tensile conditions of the actual working environment, we can ensure that the product has sufficient strength and toughness.

3. Aging test chamber:

In order to verify the stability of fluorine rubber FKM O-rings under long-term use or extreme environments, we use an aging test chamber for accelerated aging tests. The equipment accelerates the natural aging process of the material by controlling conditions such as temperature, humidity, and light, thereby evaluating its weather resistance and service life.

4. Micro Melting Point Instrument:

Although the melting point of fluororubber is relatively high, the precise measurement capability of the micro melting point instrument can help us understand the thermal stability of the material under different conditions, which is crucial for evaluating its performance in high temperature environments.

5. Rubber and Plastic Density Tester:

Density is one of the important indicators for measuring material quality. Through the rubber and plastic density tester, we can quickly and accurately determine the density of fluororubber FKM O-rings and further understand their physical properties.

6. Projector (2D):

Used to accurately measure the outer dimensions and shape accuracy of FKM O-rings to ensure that the product meets the design requirements and avoid seal failure caused by dimensional deviation.

7. Mooney Viscometer:

Viscosity is an important parameter for measuring the fluidity of materials. The Mooney Viscometer can accurately measure the viscosity of fluororubber, helping us understand its flow properties during processing and thus optimize the production process.

8. Durometer:

Hardness is an indicator for evaluating the material's ability to resist local pressure deformation. Through the durometer test, we can ensure that the hardness of the FKM O-ring meets the requirements of specific application scenarios and ensure the sealing effect.

9. Closed rotorless vulcanizer:

As a key equipment in the production process, the closed rotorless vulcanizer can accurately control the vulcanization time and temperature to ensure the vulcanization quality of the FKM O-ring, which in turn affects its final performance.

10. Thickness gauge:

Accurately measure the wall thickness of the FKM O-ring to ensure the consistency of the product and the reliability of the sealing effect.

11. Phoenix dimensional detection equipment:

High-precision three-dimensional measurement system for accurate detection of complex shapes and sizes to ensure the precise matching of FKM O-rings in three-dimensional space.

12. Double-turn rotary oil seal tester:

Simulate the oil seal performance under actual working conditions and evaluate the sealing effect and durability of FKM O-rings in rotary motion.

13. Glass disc screening machine:

Used to detect surface defects and impurities of FKM O-rings to ensure product appearance quality.

14. Hot air aging test chamber:

Complementary to the aging test chamber, it accelerates material aging through high-temperature hot air, and further verifies the high temperature resistance and aging resistance of fluororubber FKM O-rings.

15. Liquid density meter:

Although fluororubber itself is insoluble in water, the liquid density meter can be used to test the volume change of fluororubber after contact with a specific liquid medium, and indirectly evaluate its solvent resistance.

16. Flaw detector:

Use non-destructive testing technology such as ultrasonic or X-ray to check whether there are defects inside the FKM O-ring to ensure product quality.

17. Oil seal radial force detector:

Directly measure the radial force of the FKM O-ring during installation and operation, and evaluate its sealing pressure and stability.

18. High temperature creep stress relaxation tester:

In a high temperature environment, simulate the material behavior under long-term stress, evaluate the creep and stress relaxation characteristics of the FKM O-ring at high temperature, and ensure its long-term sealing performance.

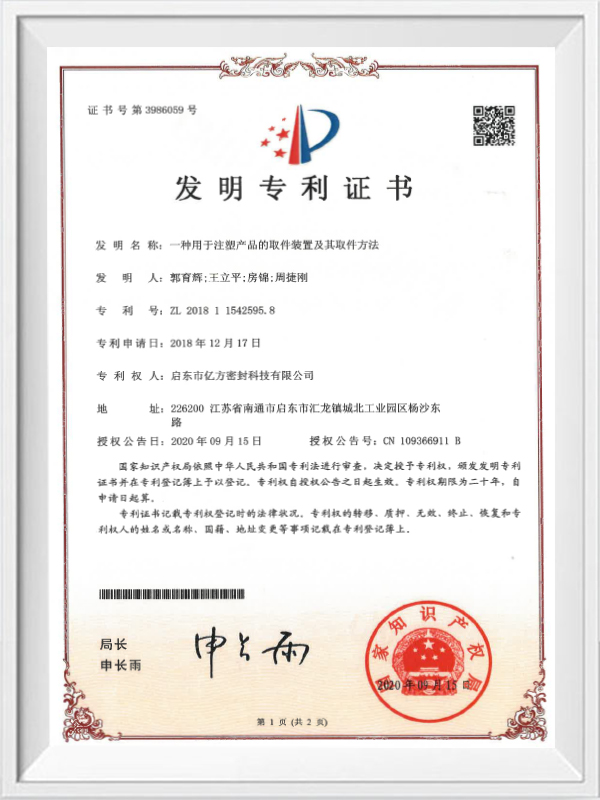

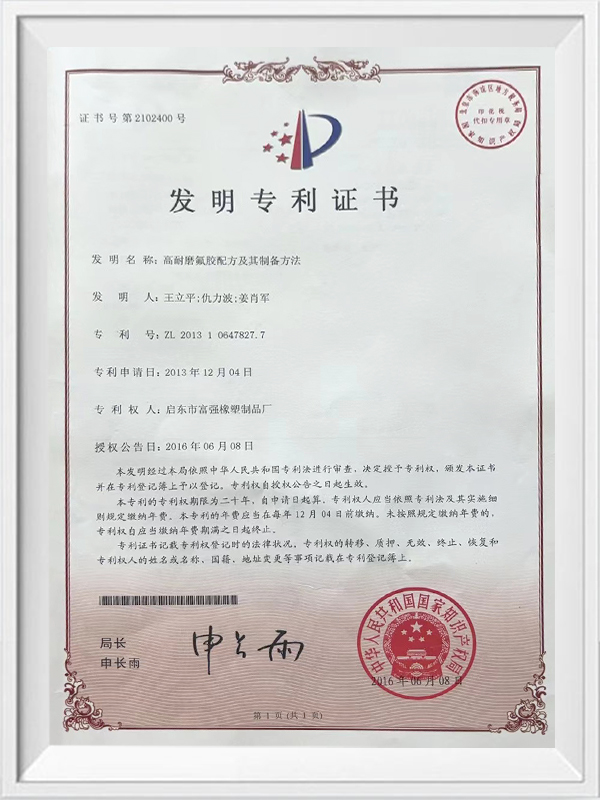

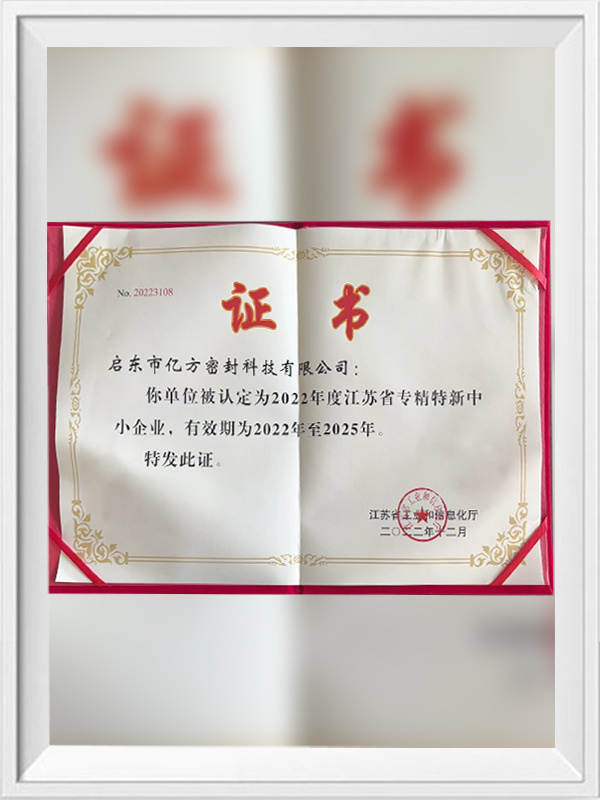

In addition to the above-mentioned advanced testing equipment and methods, the company also has a strong R&D team and has established close industry-university-research cooperation with many well-known domestic universities and research institutions. Through continuous technological innovation and R&D investment, we have obtained three invention patents and more than 30 utility model patents, further consolidating the company's leading position in the field of fluororubber FKM O-rings.

English

English русский

русский 中文简体

中文简体