-

The 25 cylinder diameter heavy electric hammer parts rubber seal ring is a critical component in hea...

READ MORE -

The bosch 26 electric hammer parts rubber seal ring is a critical component in maintaining the effic...

READ MORE -

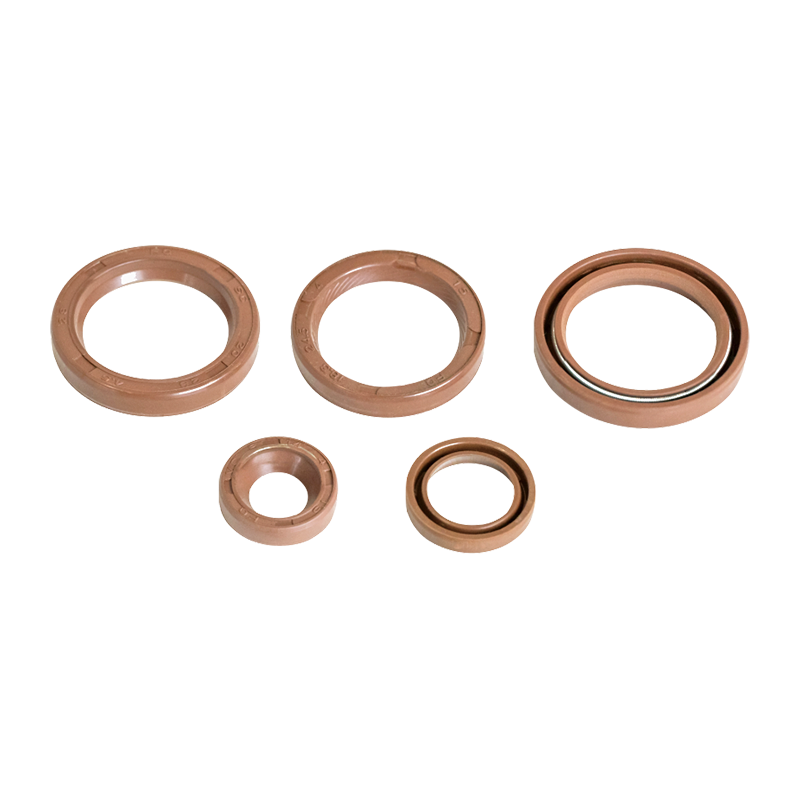

A TB Type Auto Parts Oil Seal Kit plays a crucial role in maintaining the proper functioning of auto...

READ MORE -

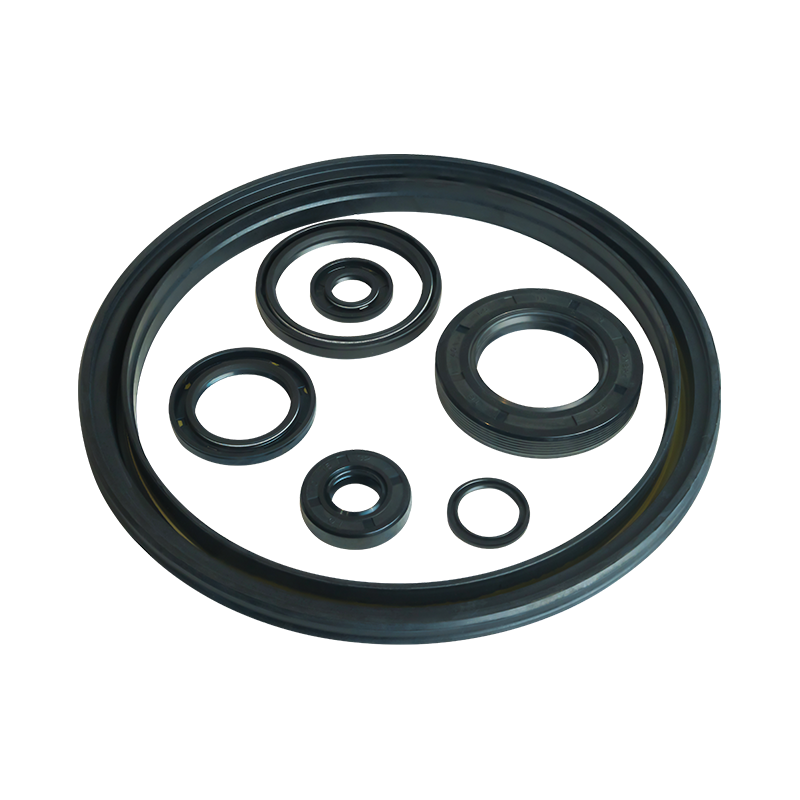

The performance and longevity of an engine depend heavily on the integrity of its components. One su...

READ MORE -

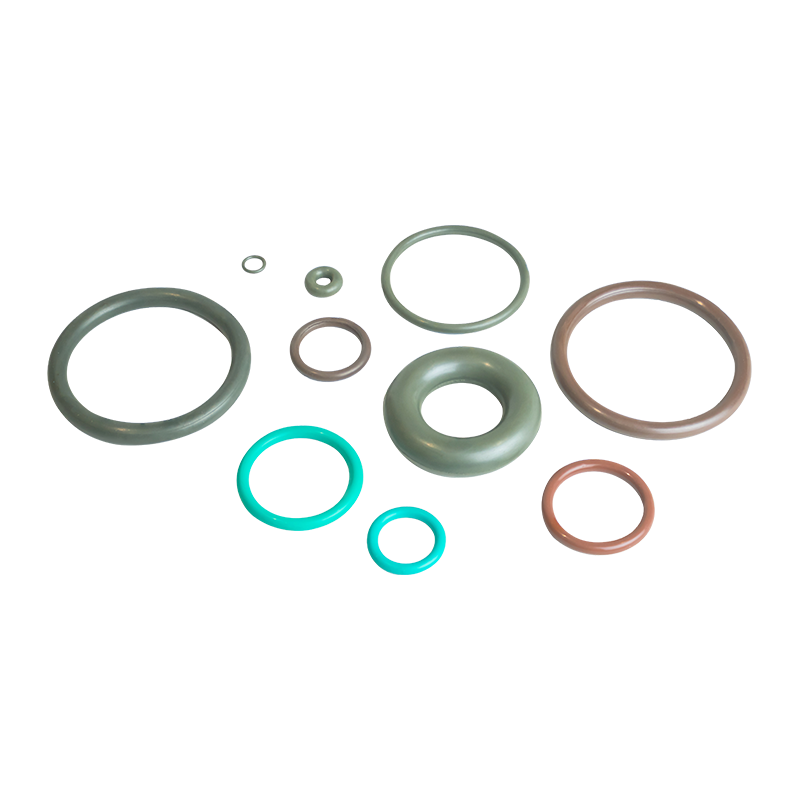

In modern automotive systems, nbr wear resistance auto parts oil seal play a crucial role in maintai...

READ MORE

In addition to material selection and process optimization, what other methods can be used to improve the high temperature resistance of FKM skeleton oil seals?

Technological innovation is the core driving force for improving product performance. The company's technical team has been exploring new high temperature resistant FKM formulas oil seal through continuous research and development, which is the key to improving the high temperature resistance of oil seals. This includes but is not limited to:

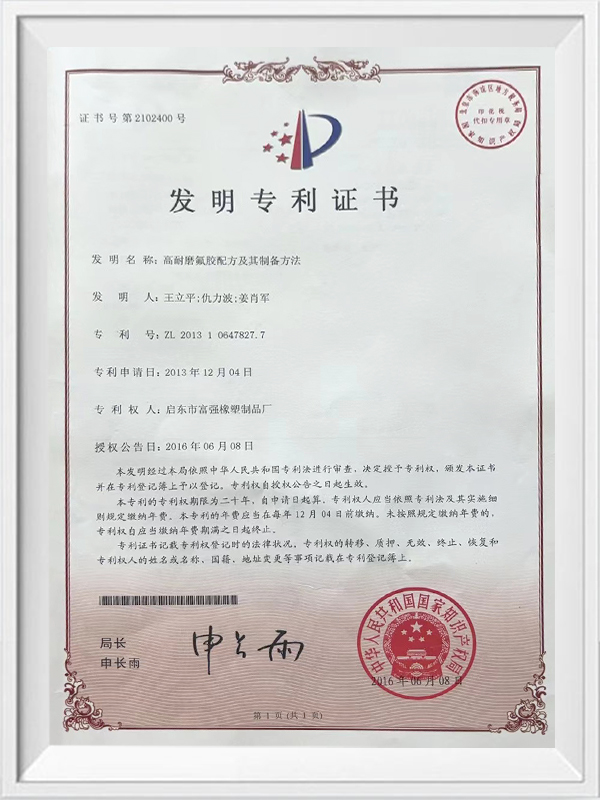

Modified FKM materials: Improve the heat resistance, aging resistance and mechanical strength of FKM by introducing specific additives or blending other polymer materials, such as nanofillers, high temperature stabilizers, etc. These additives can exist stably at high temperatures and effectively prevent the breakage of molecular chains, thereby improving the overall heat resistance of the material.

Crosslinking density regulation: By precisely controlling the degree of crosslinking of FKM, its high temperature resistance and elastic recovery can be optimized. Too high or too low crosslinking density will affect the heat resistance and sealing effect of the oil seal. Therefore, finding the optimal crosslinking density point is the key to improving performance.

Surface treatment technology: Special treatment of the surface of FKM skeleton oil seal, such as coating with high temperature resistant coating or plasma modification, can enhance its surface resistance to high temperature and wear, and improve the adhesion with metal shaft or sleeve, and extend the service life.

The company has a full set of advanced testing equipment and production lines, which provides a solid hardware foundation for improving the high temperature resistance of FKM skeleton oil seal.

Fully automatic upper auxiliary machine mixing system: ensures the precise proportion and uniform mixing of FKM raw materials, avoids the performance difference caused by uneven distribution of raw materials, and provides a stable raw material basis for the production of high-quality, high temperature resistant oil seals.

Intelligent mold library and vulcanization workshop: through intelligent management, the temperature, pressure and time in the vulcanization process are precisely controlled, the vulcanization process of FKM is optimized, and the heat resistance and dimensional stability of the oil seal are improved.

Top testing equipment: such as analytical balance, electronic tensile testing machine, aging test box, etc., can comprehensively evaluate the physical and chemical properties, heat aging resistance, etc. of FKM oil seals, ensuring that each batch of products can meet high standards of quality requirements.

Close cooperation with many domestic universities and scientific research institutions is an important source of the company's technological innovation. Through industry-university-research cooperation, the company can quickly absorb the latest scientific research results and transform them into actual productivity.

Material Science Research: Cooperate with experts in the field of material science to conduct in-depth research on the molecular structure and thermal stability mechanism of FKM, and provide a theoretical basis for the development of new high-temperature resistant FKM materials.

Process Optimization and Simulation: Use computer simulation technology to simulate the stress distribution, temperature change and wear of oil seals under different working conditions, guide process optimization, and improve the high-temperature resistance and sealing efficiency of oil seals.

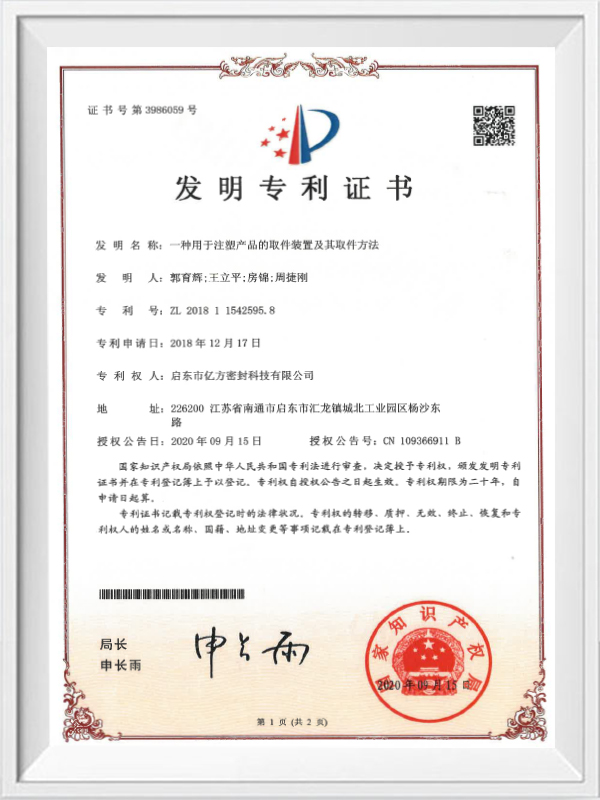

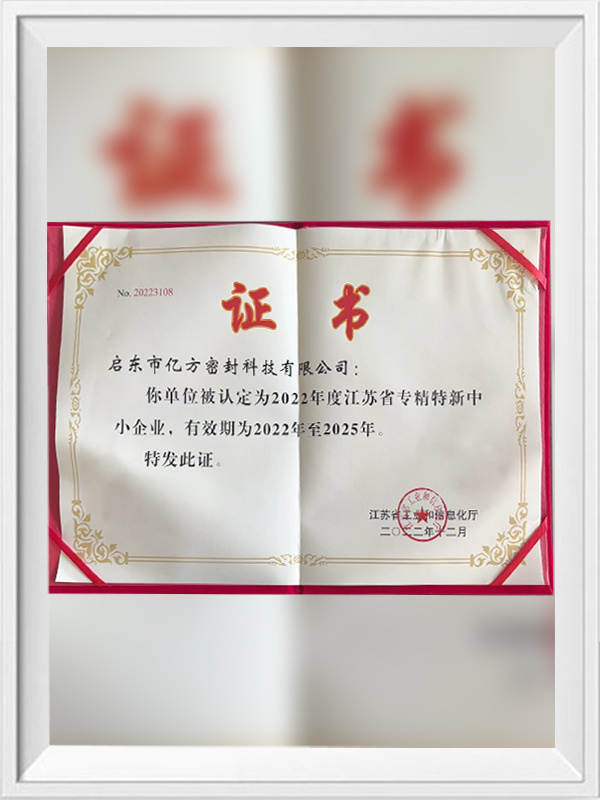

Standard Setting and Certification: Cooperate with industry associations and standard setting organizations to participate in the formulation of international standards for high-temperature resistant FKM skeleton oil seals to ensure that the company's products not only meet domestic standards, but also meet the strict requirements of the international market.

After each process in the manufacturing process, the company implements strict inspection procedures to ensure that every step is in the best condition. For the final product, the company not only conducts full inspection according to customer requirements and international standards, but also uses the most advanced testing equipment in the industry, such as Phoenix size testing equipment, double-turn rotary oil seal testing machine, etc., to conduct high-precision comprehensive testing to ensure that the oil seal's high temperature resistance, physical and chemical properties, aging resistance, etc. meet all standards.

English

English русский

русский 中文简体

中文简体