-

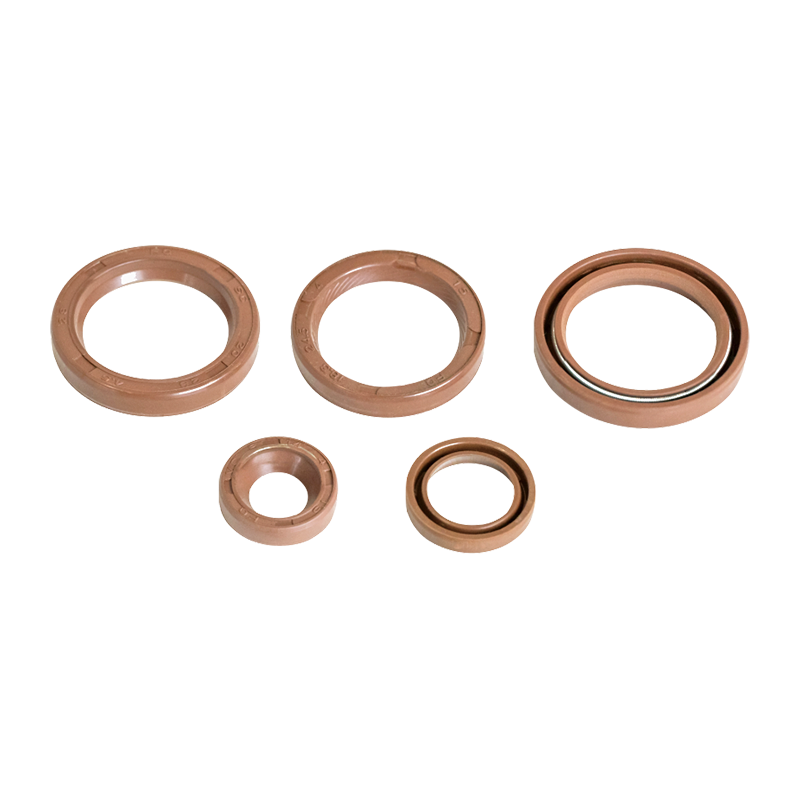

The performance and longevity of an engine depend heavily on the integrity of its components. One su...

READ MORE -

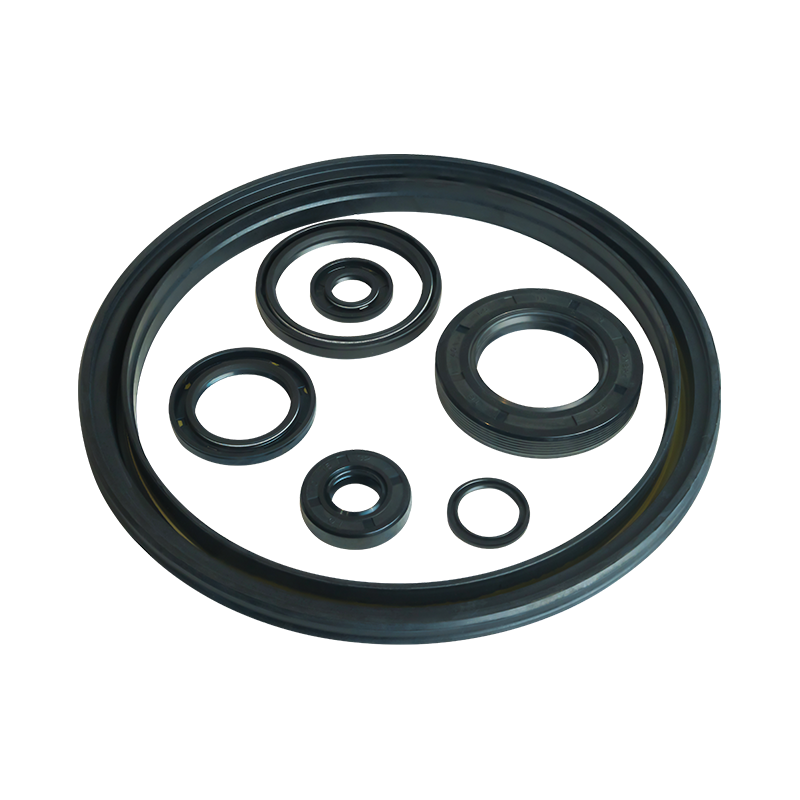

In modern automotive systems, nbr wear resistance auto parts oil seal play a crucial role in maintai...

READ MORE -

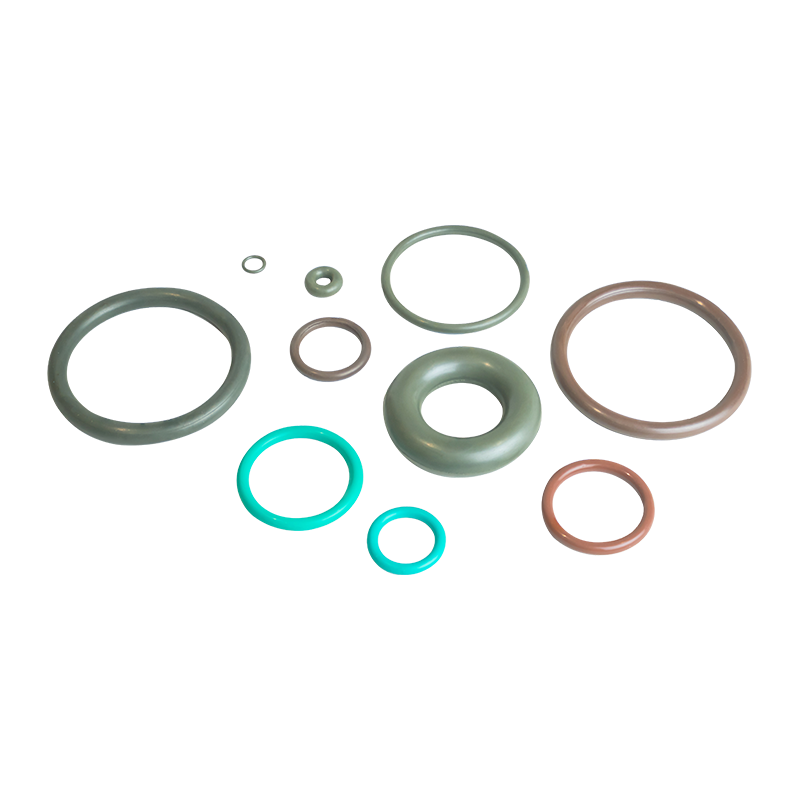

Hydrogenated nitrile (HNBR) O-Ring Seal Kits are widely used in industrial applications due to their...

READ MORE -

The evolution of FAWDE Engine Parts PTFE Oil Seal reflects the ongoing demand for higher efficiency,...

READ MORE -

Ensuring that a nbr mechanical seal rubber o-ring kit fits your equipment correctly is a critical st...

READ MORE

NBR wear-resistant auto parts oil seals will be affected by dynamic loads and vibrations during vehicle operation. Has the NBR wear-resistant auto parts oil seal manufacturer conducted relevant dynamic performance tests?

Through nearly two decades of continuous investment and innovation, we have established a complete production system, including a full set of advanced testing equipment, a fully automatic upper and auxiliary mixing system, an intelligent mold library and an intelligent vulcanization workshop. These equipment not only improve production efficiency, but also play a key role in product quality control.

Fully automatic upper auxiliary machine mixing system: This system adopts advanced automation control technology, which can accurately control the raw material ratio and mixing process, ensuring that each batch of raw materials has consistent physical and chemical properties, which provides a good foundation for subsequent oil seal manufacturing. Provide a solid foundation.

Intelligent mold library: Our mold library adopts intelligent management and can quickly respond to the production needs of different products. The precision and durability of the mold have been significantly improved, ensuring the accuracy of the size and shape of the oil seal.

Intelligent vulcanization workshop: Vulcanization is one of the key steps in the production of rubber products. Our intelligent vulcanization workshop uses advanced temperature control and vulcanization technology to accurately control the temperature and time during the vulcanization process, thereby ensuring the vulcanization quality of the oil seal.

Advanced and complete top-notch testing equipment: In order to comprehensively test the performance of oil seals, we are equipped with the most advanced testing equipment in the industry, including analytical balances, electronic tensile testing machines, aging test chambers, micro-melting point meters, rubber and plastic density meters, etc. These devices can accurately measure key indicators such as mechanical properties, aging resistance, and density of oil seals to ensure that each batch of products meets customer requirements and international standards.

We have conducted rigorous dynamic performance tests to address the dynamic loads and vibrations that may affect NBR wear-resistant auto parts oil seals during vehicle operation. These tests cover not only the mechanical properties of the oil seal, but also its durability and reliability under specific operating conditions.

Dynamic load testing: We use specialized dynamic load testing equipment to simulate various dynamic loads that the oil seal may be subjected to during vehicle operation. Through testing, we can evaluate the deformation, wear and sealing performance of the oil seal under stress, thereby ensuring that it can maintain a stable and reliable sealing effect in actual applications.

Vibration test: Vibration is one of the common phenomena during vehicle operation. In order to evaluate the performance of the oil seal in a vibration environment, we conducted vibration tests. By simulating vibrations of different frequencies and amplitudes, we can observe the response of the oil seal, including its vibration transmission characteristics, deformation and wear. These test results provide valuable basis for us to optimize the oil seal design and manufacturing process.

Durability and reliability testing: In order to ensure that the oil seal has sufficient durability and reliability in actual applications, we conducted long-term durability and reliability testing. These tests cover key indicators such as the service life, wear, and sealing performance of the oil seal under different working conditions. Through testing, we can evaluate the performance stability and reliability of the oil seal during long-term use, thereby providing customers with more reliable products.

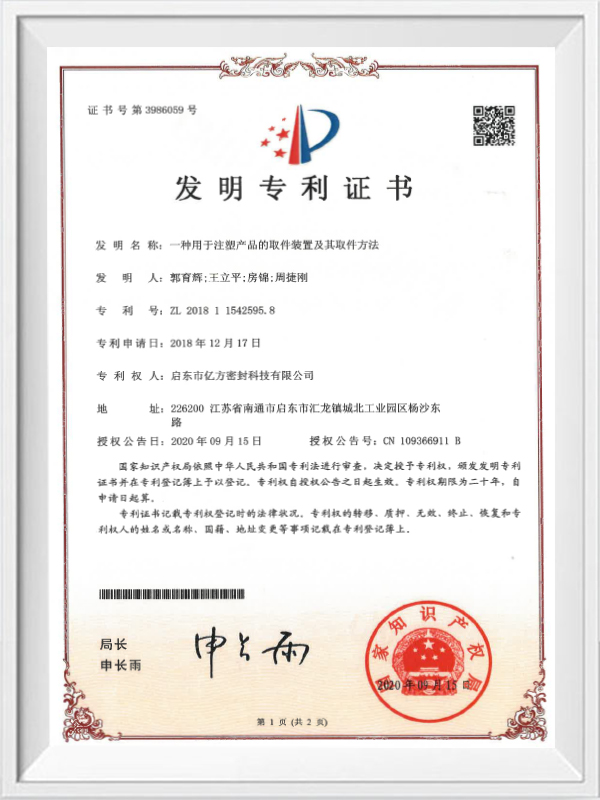

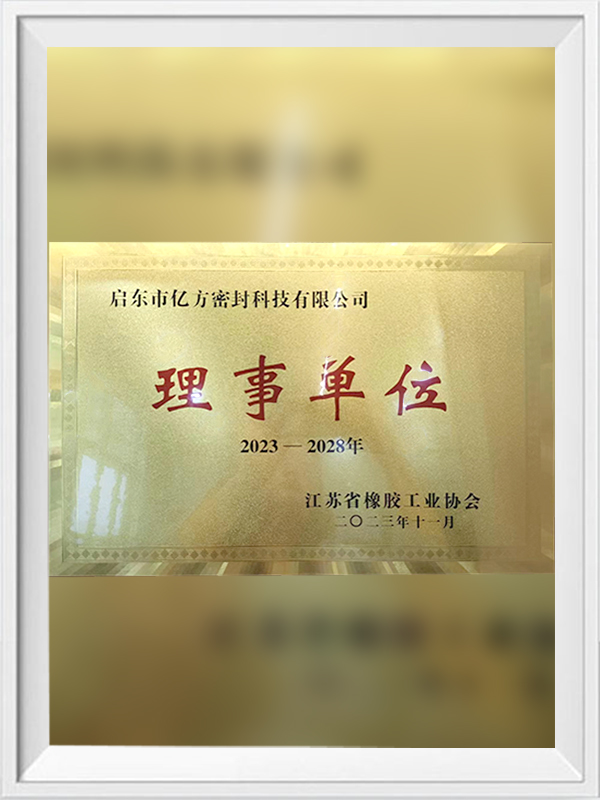

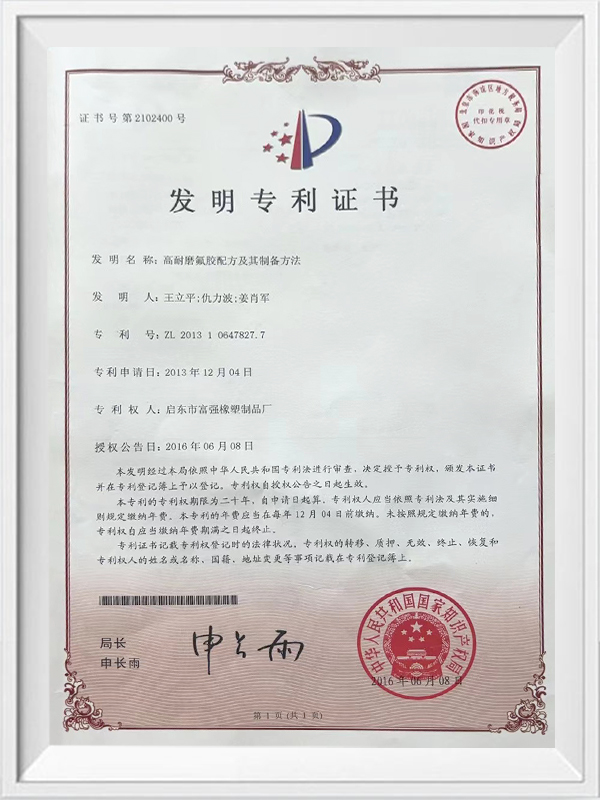

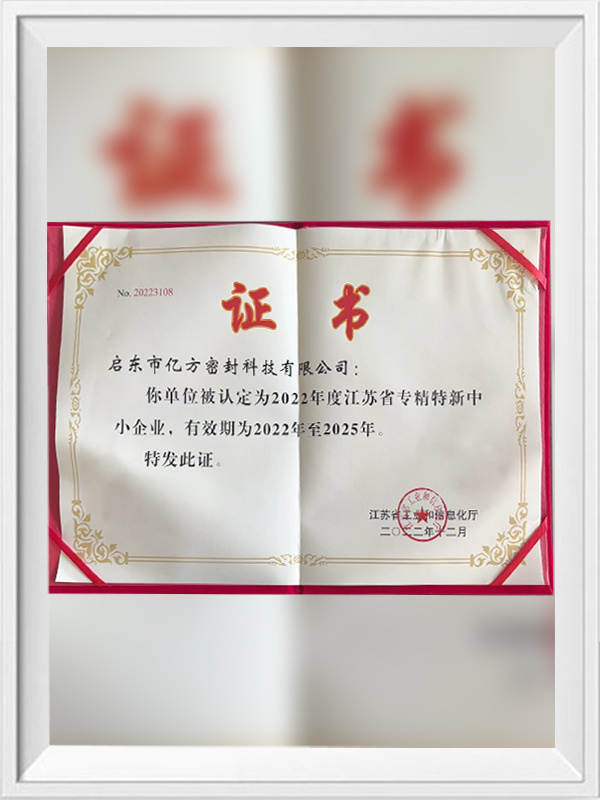

We are well aware of the importance of technological innovation to enterprise development. Therefore, we have established close industry-university-research cooperation relationships with many domestic universities and scientific research institutions. Through cooperation, we continue to introduce and digest advanced scientific research results and technologies, and apply them to actual production. At present, the company has obtained three invention patents and more than 30 utility model patents. These patents not only enhance our technical strength, but also provide strong support for us to develop new products and optimize existing products.

English

English русский

русский 中文简体

中文简体