Fluorine rubber FKM O-ring seal: in-depth analysis and application strategy of low-temperature sealing performance

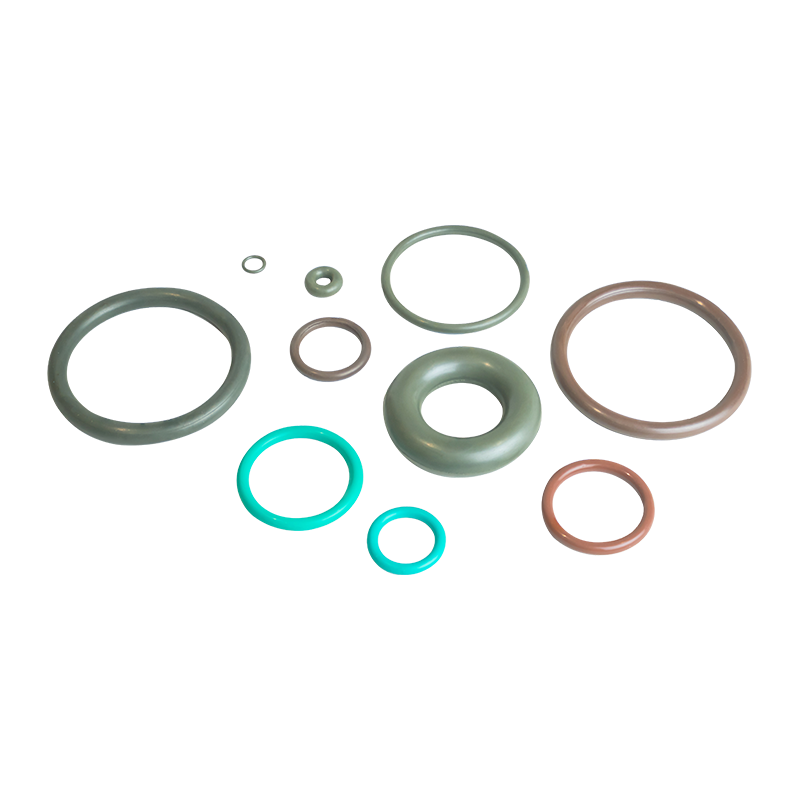

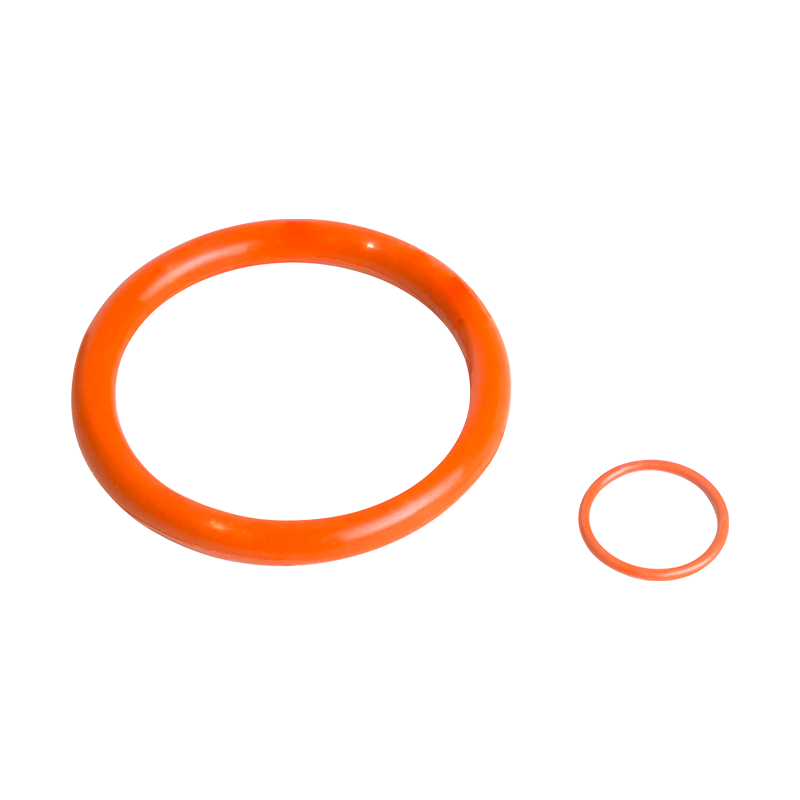

FKM (Fluorocarbon Rubber) occupies a pivotal position in many industrial fields with its excellent chemical resistance, high temperature resistance and good mechanical properties. Especially in occasions that need to withstand extreme environmental conditions, such as petrochemical industry, aerospace, automobile manufacturing, etc., fluororubber FKM O-ring seals have become indispensable sealing components. However, with the diversification of application environments, the performance of fluororubber FKM under low temperature conditions has gradually attracted people's attention. Sealing rings harden at low temperatures and may not be able to effectively fill the sealing gap, resulting in a significantly increased risk of leakage. When selecting fluororubber FKM O-rings, an in-depth evaluation of its low-temperature sealing performance is particularly important. If necessary, low-temperature sealing performance testing is also required to ensure its reliability under specific working conditions.

The hardening phenomenon of fluororubber FKM in low temperature environments is a direct result of the reduced activity of its molecular chain structure at low temperatures. As the temperature decreases, the vibration frequency and amplitude of the fluororubber FKM molecular chain decreases, and the interaction force between chain segments increases, resulting in an increase in the overall hardness of the material, an increase in elastic modulus, and a decrease in resilience and sealing performance. This hardening phenomenon not only limits the deformation ability of the seal ring at low temperatures, making it difficult to effectively fill the sealing gap caused by thermal expansion and contraction, but may also cause fracture during installation or use due to the increased brittleness of the material.

The sealing performance challenges of fluororubber FKM O-rings in low temperature environments are mainly reflected in the following aspects:

Sealing gap filling capacity:

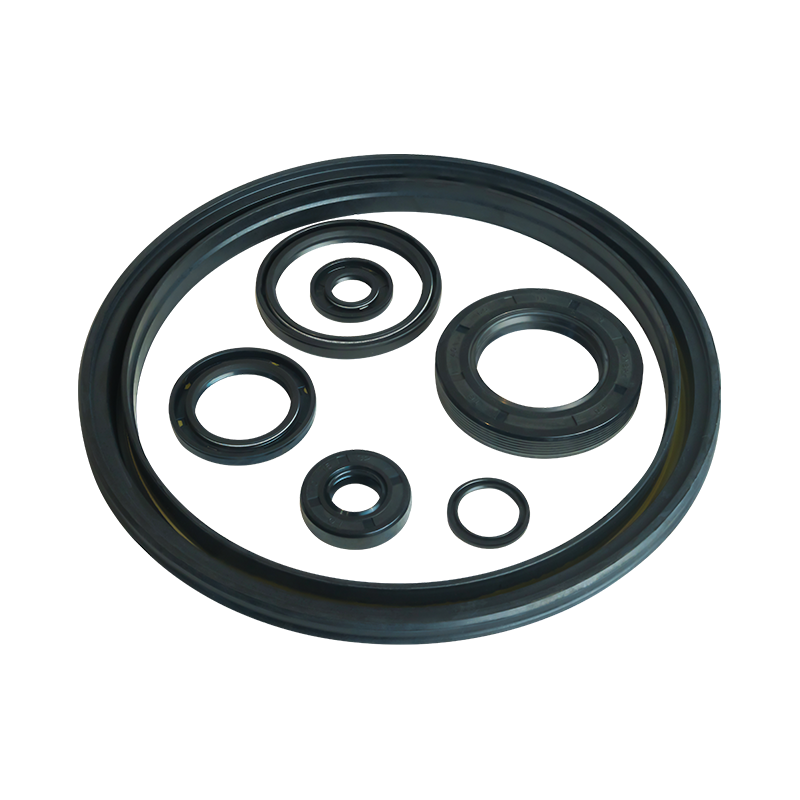

Low-temperature hardening causes the sealing ring to harden, and its ability to fill the sealing gap decreases, which may lead to loose sealing and increase the risk of leakage. Especially in dynamic sealing applications, such as rotating shafts or reciprocating seals, the hardened seal may fail due to its inability to respond to gap changes in a timely manner.

Stress relaxation and creep:

When subjected to low-temperature stress for a long time, fluororubber FKM may undergo stress relaxation or creep, resulting in further degradation of sealing performance. This phenomenon is particularly noticeable in static sealing applications, such as flange joint sealing.

Material brittleness and fracture:

The brittleness of fluororubber FKM increases at low temperatures, making it more susceptible to fracture when subjected to external forces. This not only affects the service life of the sealing ring, but may also directly lead to seal failure and cause safety accidents.

In order to ensure the sealing performance of fluororubber FKM O-rings in low temperature environments, they must be rigorously evaluated and tested. This includes but is not limited to the following aspects:

Low temperature hardness test:

Through the low-temperature hardness test, the hardness change of fluororubber FKM at a specific low temperature can be understood to evaluate its degree of hardening and its impact on the sealing gap filling ability.

Low temperature rebound performance test:

Resilience performance reflects the ability of a sealing ring to quickly return to its original shape after being compressed. The low-temperature rebound performance test can evaluate the elastic recovery ability of fluororubber FKM at low temperatures to ensure that it can effectively fill gaps during the sealing process.

Low temperature sealing performance test:

The most direct method is to test the sealing performance of fluororubber FKM O-rings in a low-temperature environment that simulates actual working conditions. This includes pressure testing, leakage rate testing, and durability testing to fully evaluate its sealing effect and service life at low temperatures.

Material compatibility testing:

In low temperature environments, fluororubber FKM may react chemically with the media or materials in contact, resulting in performance degradation. Therefore, material compatibility testing is also an important part of ensuring the low-temperature sealing performance of sealing rings.

To address the sealing performance challenges of fluororubber FKM O-rings in low-temperature environments, the following strategies and solutions can be adopted:

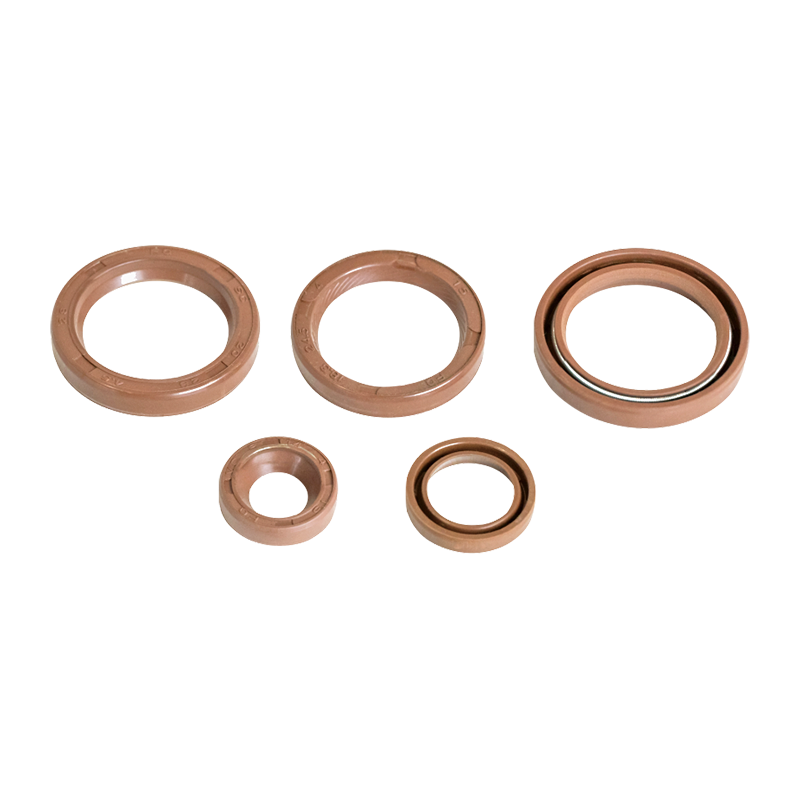

Material selection and formula optimization:

By adjusting the formula of fluororubber FKM, such as adding plasticizers, cold-resistant agents, etc., its low-temperature performance can be improved, and the softness and resilience of the sealing ring can be improved. However, it should be noted that the addition of plasticizer may affect the chemical corrosion resistance and high temperature resistance of fluororubber FKM, so a balance point needs to be found between comprehensive performance.

Dimensional design and preload adjustment:

In the design stage of the sealing ring, the problem of insufficient sealing gap filling capacity caused by low-temperature hardening can be compensated by increasing the cross-sectional size of the sealing ring, adopting special shape design (such as cone, trapezoid, etc.) and increasing preload force. . At the same time, reasonable preload setting can also improve the sealing effect and service life of the sealing ring.

Environmental simulation and adaptability testing:

Before formal application, the fluororubber FKM O-ring was subjected to simulation testing in a low-temperature environment to evaluate its sealing performance under actual working conditions. This helps identify potential problems and take corrective measures in advance to ensure the reliability and safety of the seal in low-temperature environments.

Alternative solutions and alternative materials:

For extreme low temperature environments or specific application requirements, if fluororubber FKM cannot meet the sealing requirements, other materials with better low temperature performance can be considered as alternatives, such as silicone rubber, polytetrafluoroethylene (PTFE), etc. These materials have better softness and resilience at low temperatures and can better adapt to changes in the sealing gap.

As a high-performance sealing element, the sealing performance of fluororubber FKM O-ring in low temperature environment is one of the key factors for its reliability. By in-depth understanding of the low-temperature hardening phenomenon of fluororubber FKM, the challenges of evaluating its low-temperature sealing performance, and adopting corresponding application strategies and solutions, the sealing effect and service life of fluororubber FKM O-rings can be ensured under specific working conditions. With the continuous advancement of material science and the increasing improvement of testing technology, the low-temperature sealing performance of fluororubber FKM O-rings is expected to be further improved in the future, providing a more reliable choice for more sealing applications in low-temperature environments.

Sray up to date with allour recent products

- Address: No. 6 Yangsha Road, Chengbei Industrial Park, Huilong Town, Qidong City, Jiangsu Province China

- Phone: +86-13906283641+86-18934546679

- Fax: +86-0513-83698022

- Email: [email protected]

English

English русский

русский 中文简体

中文简体