NBR Mechanical Seal Rubber O-Ring Kit: The Art and Science of Surface Preparation

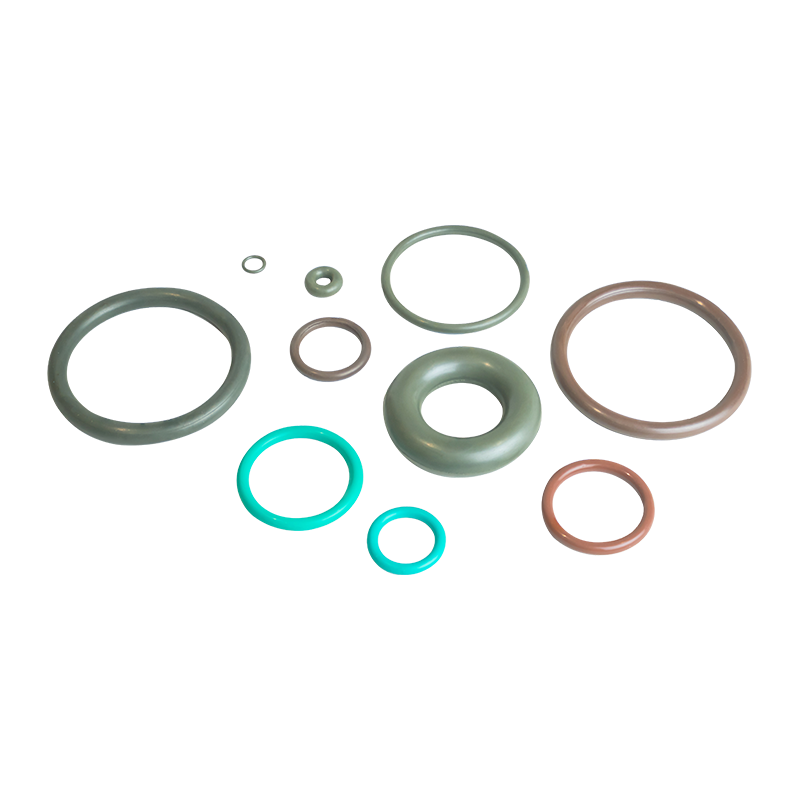

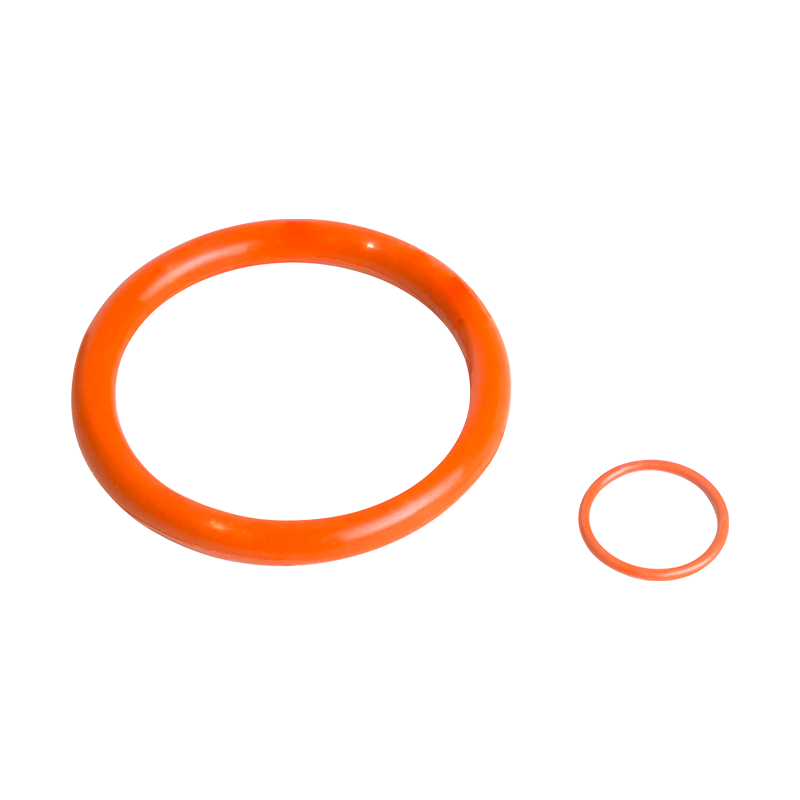

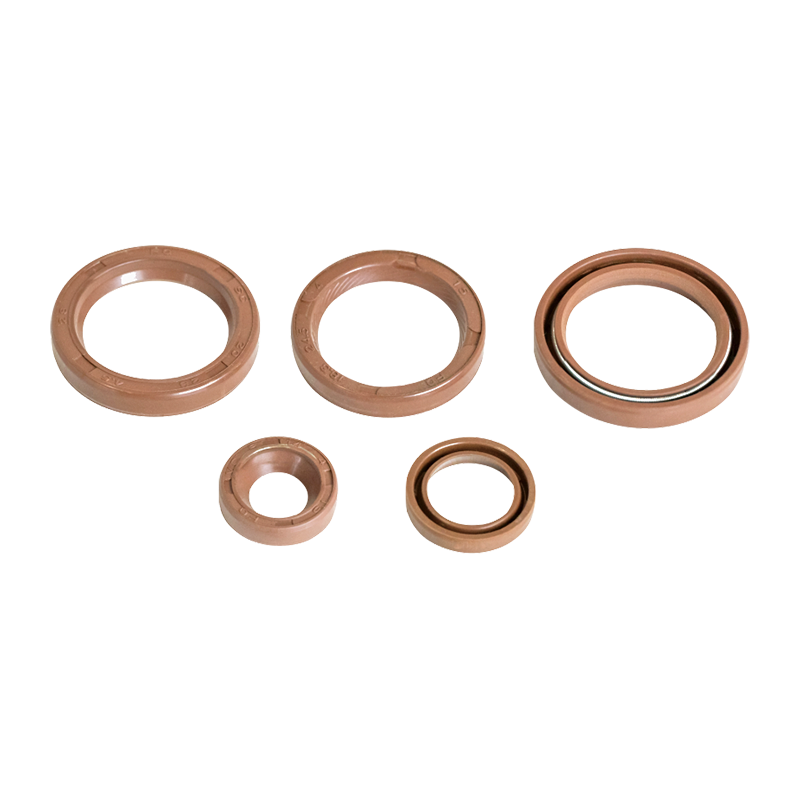

Seals play a vital role in the operation of precision machinery and complex industrial systems. Among them, NBR (nitrile rubber) mechanical seal rubber O-ring kit stands out in many industrial applications due to its excellent oil resistance, wear resistance and chemical corrosion resistance, and has become a key component to ensure the stable operation of equipment. However, even with highly sophisticated manufacturing processes, the surface of the formed O-ring kit may contain minor imperfections, such as burrs, bulges or uneven areas. Although these tiny flaws may seem inconspicuous, they are enough to significantly affect the sealing performance and wear resistance of the O-ring. Surface treatment has become an integral part of improving the performance of NBR mechanical seal rubber O-ring kits. It is both an art and a science.

During the production process of NBR mechanical seal rubber O-ring kit, due to the characteristics of the rubber material, the accuracy of the mold and the control of the molding process, a series of defects may occur on the surface. These defects may originate from factors such as impurities in the rubber raw material, tiny scratches on the mold surface, uneven temperatures or pressure fluctuations during the molding process. Although most defects are difficult to detect with the naked eye, they are enough to destroy the close contact between the O-ring and the sealing surface, leading to a decrease in sealing performance and even leakage. In addition, defects may also become stress concentration points, accelerate the wear of the O-ring and shorten its service life.

In order to eliminate these surface defects and improve the sealing performance and wear resistance of the O-ring kit, surface treatment is particularly important. The goal of surface treatment is not only to smooth the surface of the O-ring kit and remove all defects that may affect the sealing effect, but also to enhance the hardness and wear resistance of the rubber surface, thereby extending its service life. An O-ring kit with careful surface treatment can maintain a stable sealing effect under harsh working conditions, reduce the risk of leakage, and resist wear, ensuring long-term stable operation of the equipment.

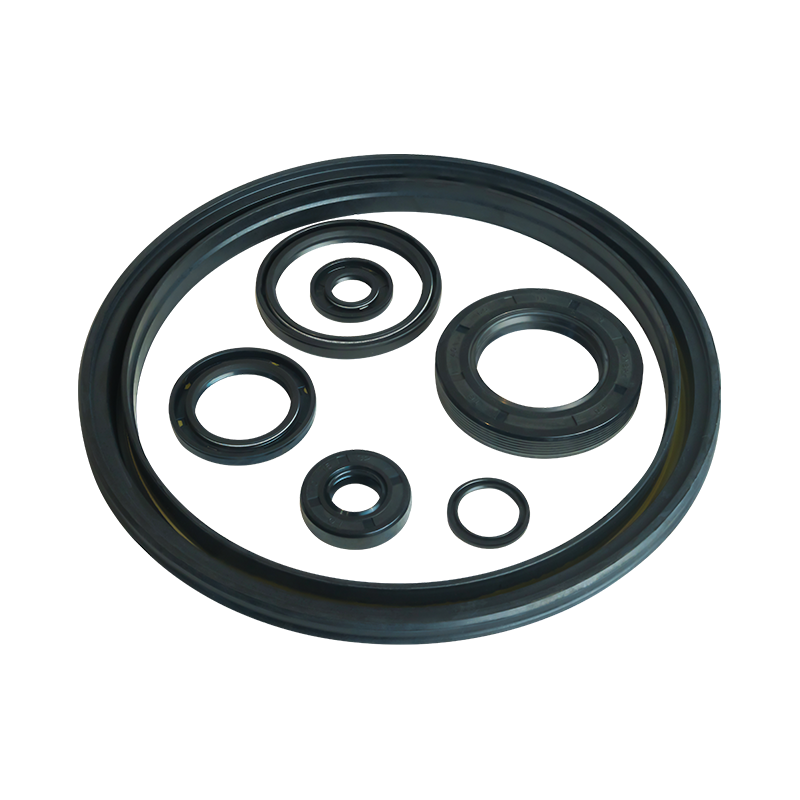

The surface treatment of NBR mechanical seal rubber O-ring kit involves a variety of technologies and methods, each method has its unique advantages and applicable scenarios. The following are some common surface treatment technologies and methods:

Grinding and polishing:

Grinding and polishing are one of the most common surface treatment methods. By using abrasive tools or polishing compounds, the surface of the O-ring kit is physically treated to remove surface imperfections and achieve smoothness. The precision and effectiveness of grinding and polishing depend on the tools used, the type of abrasive and the processing time. For O-ring kits with higher requirements, a multi-stage grinding and polishing process may be required to ensure the best surface quality.

Chemical treatment:

Chemical treatment involves soaking, spraying or brushing the surface of the O-ring kit with a specific chemical solution to change the microstructure and chemical properties of the rubber surface. This treatment enhances the hardness, wear resistance and corrosion resistance of the rubber surface. The choice of chemical treatment depends on the operating environment and usage requirements of the O-ring kit. For example, O-ring kits working in highly corrosive media may require the use of chemical treatment fluids with anti-corrosion functions.

Coating treatment:

Coating treatment is to apply a thin layer of wear-resistant, corrosion-resistant or special-function material on the surface of the O-ring kit. These coating materials can be metals, ceramics, polymers, etc., which can significantly improve the wear resistance, corrosion resistance and sealing performance of the O-ring kit. The key to coating treatment is to select the appropriate coating material, control the coating thickness and uniformity, and ensure a good bond between the coating and the rubber substrate.

Plasma treatment:

Plasma treatment is an advanced surface treatment technology that uses plasma to bombard and modify the surface of the O-ring kit to improve the microstructure and chemical properties of the surface. Plasma treatment can enhance the wettability, adhesion and wear resistance of the rubber surface, while reducing the friction coefficient and wear rate of the surface. This processing method is particularly suitable for O-ring kits that require high precision and performance.

Laser treatment:

Laser processing is a technology that uses a laser beam to precisely machine and modify the surface of an O-ring kit. By adjusting the parameters of the laser (such as power, wavelength and scanning speed), micro-nano processing, texturing or hardening of the surface of the O-ring kit can be achieved. Laser treatment can significantly improve the hardness, wear resistance and sealing performance of the O-ring kit surface, while reducing the surface roughness and friction coefficient.

Quality control and inspection

After the surface treatment is completed, it is crucial to carry out strict quality control and inspection of the NBR mechanical seal rubber O-ring kit. This includes using high-precision instruments such as microscopes and scanning electron microscopes to inspect surface quality, measuring physical properties such as coating thickness and hardness, and conducting sealing performance tests and wear resistance tests. Through these inspection methods, we can ensure that each O-ring kit meets the established quality standards and performance requirements, thereby ensuring the stable operation and reliability of the equipment.

The surface treatment of NBR mechanical seal rubber O-ring kit is a complex and delicate work, which involves the selection and application of multiple technologies and methods. Through effective surface treatment, the sealing performance and wear resistance of the O-ring kit can be significantly improved, extending its service life and ensuring the stable operation of the equipment under various complex working conditions. Therefore, for manufacturers and users of NBR mechanical seal rubber O-ring kits, paying attention to and optimizing the surface treatment process is an important part of achieving efficient, safe and reliable industrial production.

Sray up to date with allour recent products

- Address: No. 6 Yangsha Road, Chengbei Industrial Park, Huilong Town, Qidong City, Jiangsu Province China

- Phone: +86-13906283641+86-18934546679

- Fax: +86-0513-83698022

- Email: [email protected]

English

English русский

русский 中文简体

中文简体