Red Silicone O-Ring Seals: A Performance Leap Through the Vulcanization Process

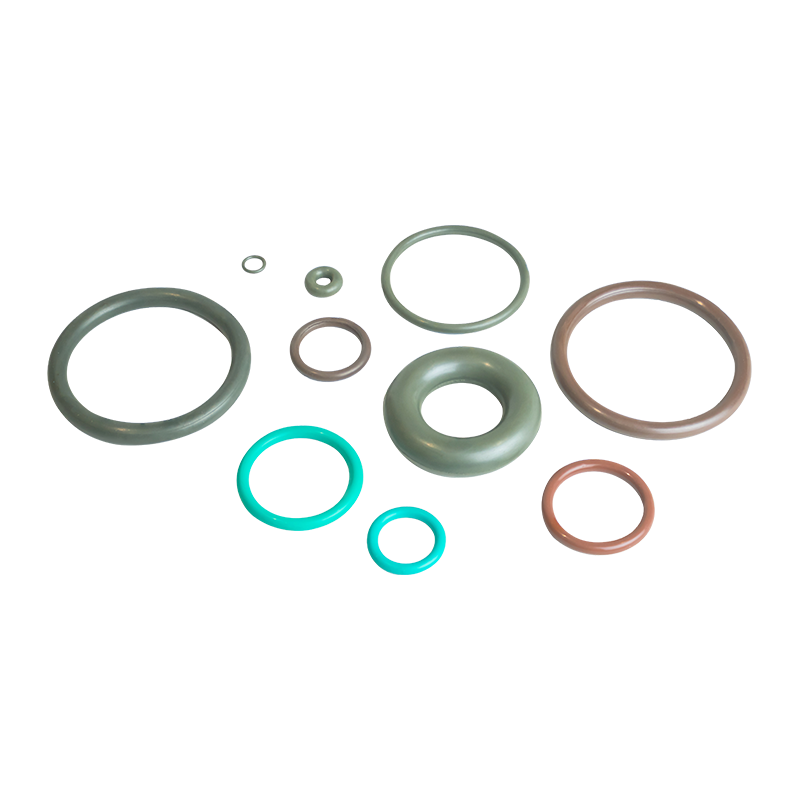

In the vast arena of modern industry and manufacturing, seals are key elements of connection and protection. The stability and reliability of their performance are directly related to the operational efficiency and safety of the entire system. Among many seals, red silicone O-rings have become the first choice in many industrial fields due to their unique material characteristics, wide applicability and excellent sealing effect. The cornerstone of this outstanding performance is largely due to the key technology of vulcanization treatment. Regardless of thermal vulcanization or chemical vulcanization, the vulcanized red silicone O-ring has shown significant performance improvements, providing strong support for sealing needs in various complex environments.

Vulcanization, as an important step in the processing of silicone materials, can significantly improve the physical and chemical properties of the material by triggering cross-linking reactions between silicone molecular chains to form a stable network structure. For red silicone O-rings, vulcanization treatment not only enhances its basic performance, but also gives it more ability to cope with complex environmental challenges.

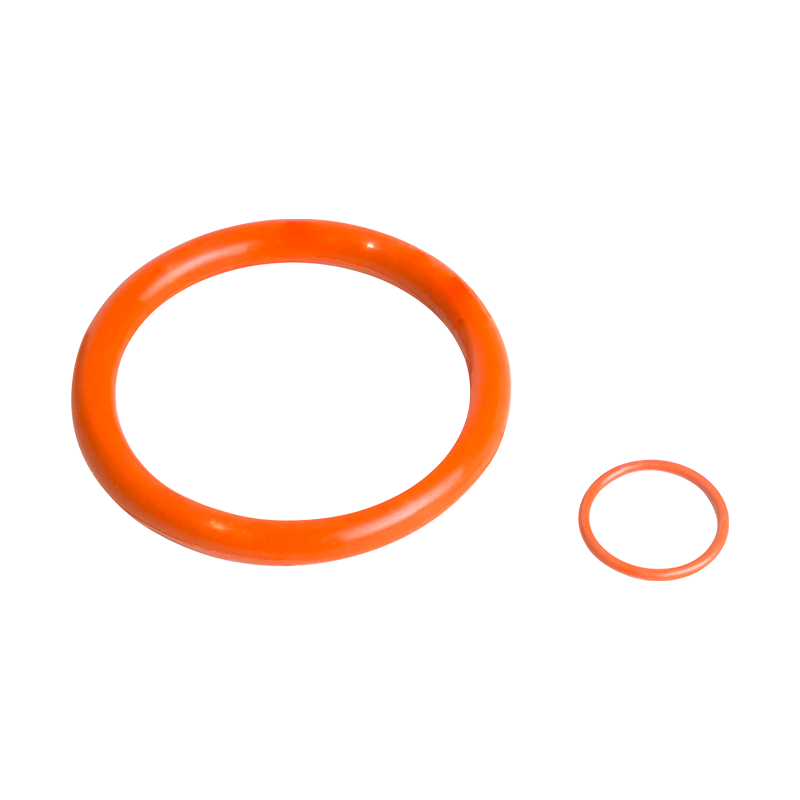

Thermal vulcanization, as a traditional method of vulcanization treatment, works by placing the formed O-ring in a vulcanization furnace, and through precisely controlled temperature and time conditions, the silica gel molecular chain is prompted to undergo a cross-linking reaction. This process not only requires uniform temperature distribution in the vulcanization furnace, but also requires strict control of the vulcanization time to ensure that the O-ring reaches the ideal degree of vulcanization. After hot vulcanization, the hardness of the red silicone O-ring is significantly improved, which can better maintain its shape when under pressure and effectively prevent leakage. At the same time, the formation of the cross-linked structure also increases the elastic modulus of silicone and improves the resilience and sealing ability of the O-ring. Thermal vulcanization also significantly improves the heat resistance of silicone, allowing the O-ring to maintain stable performance in high temperature environments without softening or deformation, thereby ensuring the durability of the sealing effect.

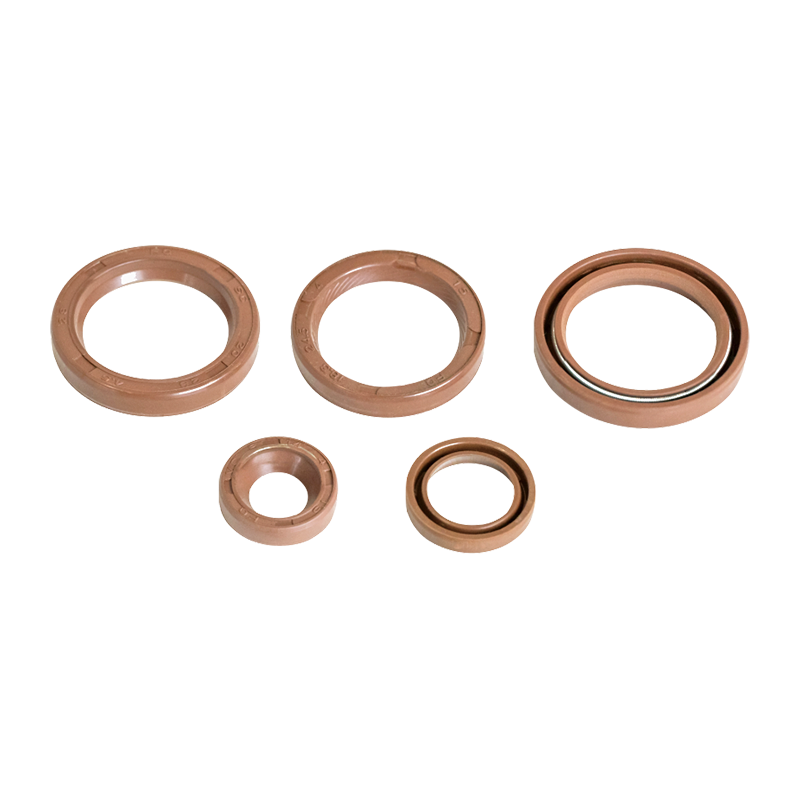

Different from thermal vulcanization, chemical vulcanization uses a specific chemical vulcanizing agent to chemically react with the silicone O-ring material to achieve the purpose of vulcanization. This process is usually carried out under specific temperatures and pressures to ensure that the vulcanizing agent fully contacts and reacts with the silicone. Chemical vulcanization can more accurately control the degree of vulcanization and cross-linking density, allowing the O-ring to maintain higher hardness and elastic modulus while achieving better chemical resistance and weather resistance. By selecting appropriate vulcanizing agents and optimizing reaction conditions, the comprehensive performance of red silicone O-rings can be further improved to meet a wider range of application needs.

The performance improvement of the vulcanized red silicone O-ring is not only reflected in the increase in hardness and elastic modulus, but also in the significant improvement in key properties such as heat resistance, chemical corrosion resistance, and aging resistance. These performance improvements enable red silicone O-rings to cope with sealing challenges in various complex environments.

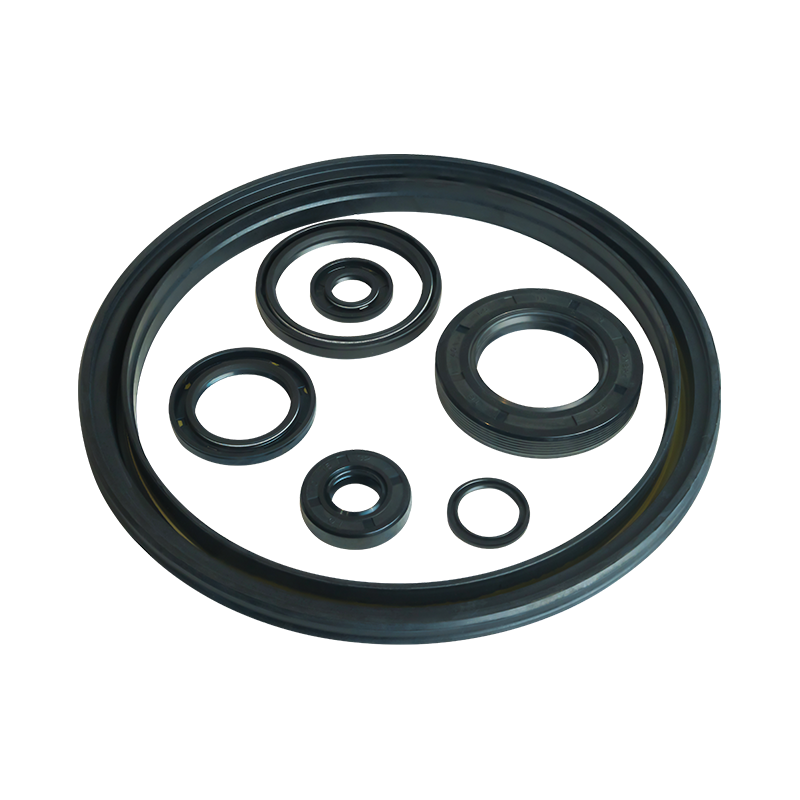

The hardness of the vulcanized red silicone O-ring is significantly improved, allowing the O-ring to better maintain its shape when under pressure and prevent leakage. This feature is particularly important in high-pressure, high-flow fluid sealing. For example, in petroleum, chemical and other industries, the sealing of pipelines and valves often faces challenges of high temperature, high pressure and corrosive media. With its high hardness and good shape retention ability, red silicone O-rings can ensure the durability and reliability of the sealing effect, effectively prevent media leakage, and ensure production safety.

The vulcanization treatment not only increases the hardness of the red silicone O-ring, but also increases its elastic modulus and improves its resilience. This characteristic enables the O-ring to better adapt to deformation when subjected to dynamic loads and maintain a stable sealing effect. For example, in the automotive industry, various pipes and sensors in the engine compartment need to withstand vibration and shock loads. With its excellent resilience and sealing ability, the red silicone O-ring can maintain a stable sealing effect under complex working conditions and ensure the normal operation of the engine.

The vulcanized red silicone O-ring has significantly improved heat resistance and chemical resistance, allowing the O-ring to maintain stable performance in harsh environments such as high temperatures and corrosive media. This feature is particularly important in industries such as food, medical, and electronics. For example, in food processing equipment, O-rings need to withstand the erosion of high-temperature steam and corrosive cleaning agents. Red silicone O-rings, with their excellent heat resistance and chemical resistance, can ensure the durability of the sealing effect and food safety.

Red silicone O-ring seals play an important role in various fields with their excellent performance and wide applicability. In the petroleum and chemical industries, red silicone O-rings are widely used to seal pipes, valves, pumps and other equipment; in the automotive industry, red silicone O-rings are used to seal various pipelines and sensors in the engine compartment. Sealing; in the food and medical industries, red silicone O-rings are widely used for sealing food processing equipment and medical equipment because of their non-toxic, odorless, high temperature resistance and chemical corrosion resistance. In addition, red silicone O-rings are also widely used in aerospace, electronic appliances, water treatment and other fields, providing strong support for sealing needs in various complex environments.

Vulcanization treatment is a key link in improving the performance of red silicone O-rings. Through thermal vulcanization or chemical vulcanization, the key properties of the O-rings such as hardness, elastic modulus, heat resistance, and chemical corrosion resistance are significantly improved. These performance improvements enable red silicone O-rings to cope with sealing challenges in various complex environments, providing strong support for the sealing needs of many industrial fields. With the continuous development of material science and manufacturing technology, the performance of red silicone O-rings will be further improved and its application fields will be broader, contributing more to industrial manufacturing and technological progress.

Sray up to date with allour recent products

- Address: No. 6 Yangsha Road, Chengbei Industrial Park, Huilong Town, Qidong City, Jiangsu Province China

- Phone: +86-13906283641+86-18934546679

- Fax: +86-0513-83698022

- Email: [email protected]

English

English русский

русский 中文简体

中文简体