Why can FKM fluororubber skeleton oil seals maintain long-term reliability under high temperature and high pressure?

Compression deformation performance refers to the degree to which the shape and size of the sealing material change over time after being subjected to a certain pressure. This indicator is crucial for sealing materials because it is directly related to whether the seal can maintain an effective sealing effect for a long time. Under high temperature environments, sealing materials often suffer from reduced compression deformation performance due to thermal expansion, softening or chemical degradation, which in turn causes seal failure. Therefore, low compression permanent deformation rate under high temperature has become an important criterion for measuring the performance of sealing materials.

FKM fluororubber, as a high-performance elastomer material, has excellent compression deformation performance under high temperature and high pressure environments with its excellent high temperature resistance, chemical corrosion resistance and oxidation resistance. Compared with other sealing materials, FKM fluororubber has a particularly outstanding low compression permanent deformation rate under high temperature. This means that even under long-term high temperature and high pressure, FKM fluororubber can maintain the stability of its shape and size, thereby ensuring the effective maintenance of the sealing gap.

The reason why FKM fluororubber can maintain a low compression permanent deformation rate at high temperature is mainly due to its unique chemical structure and physical properties. The main chain of FKM fluororubber is composed of carbon-fluorine bonds, which have high bond energy, making FKM fluororubber have high thermal stability and chemical stability. In addition, the fluorine atoms in FKM fluororubber have large electronegativity, which can form strong intermolecular interaction forces, thereby enhancing the mechanical strength and elastic modulus of the material. These characteristics together enable FKM fluororubber to maintain a stable shape and size under high temperature and high pressure, thereby ensuring the durability of the sealing effect.

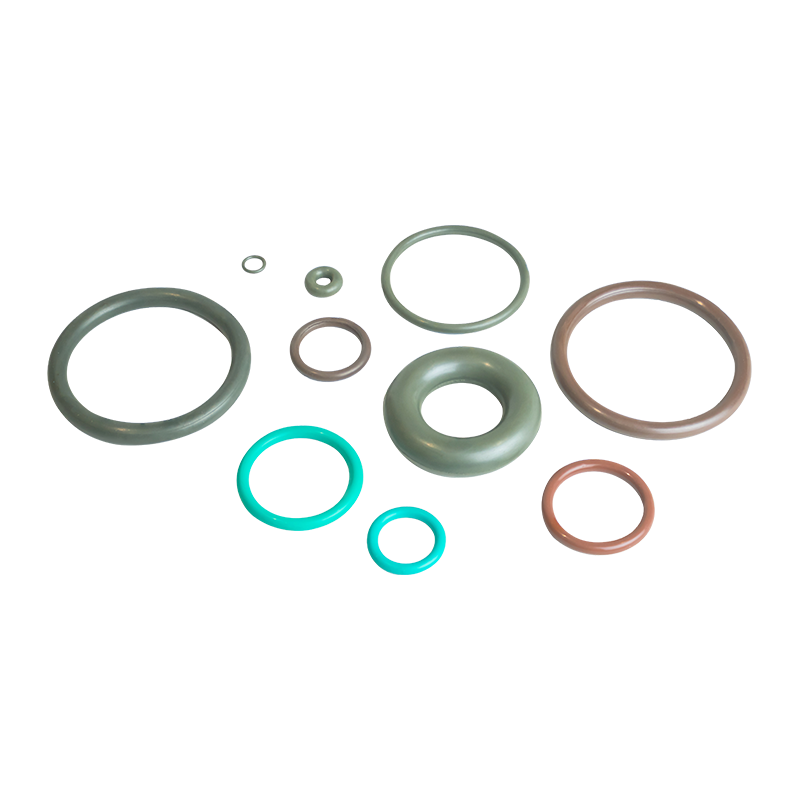

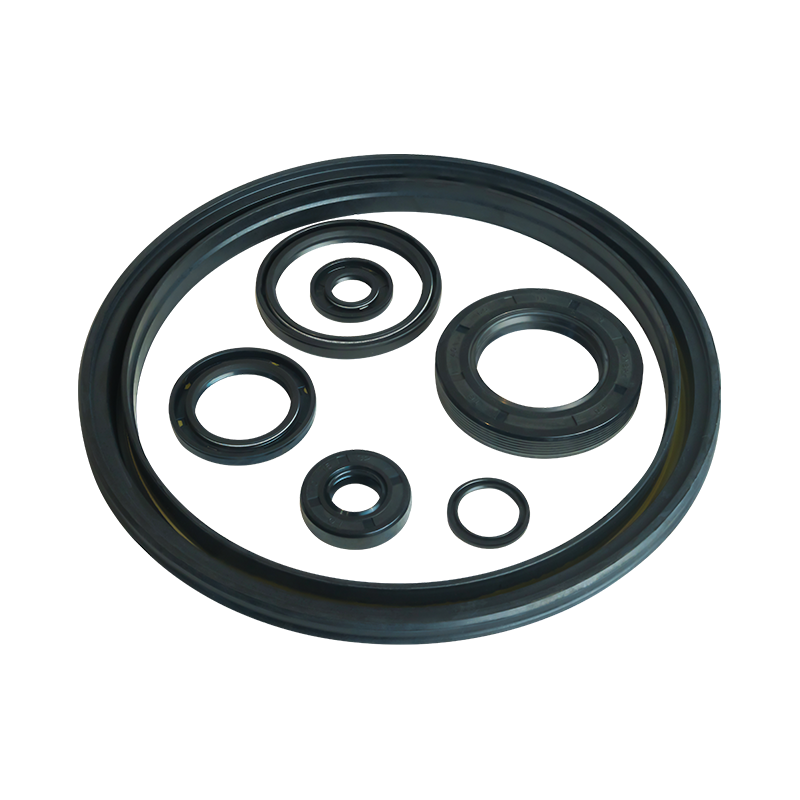

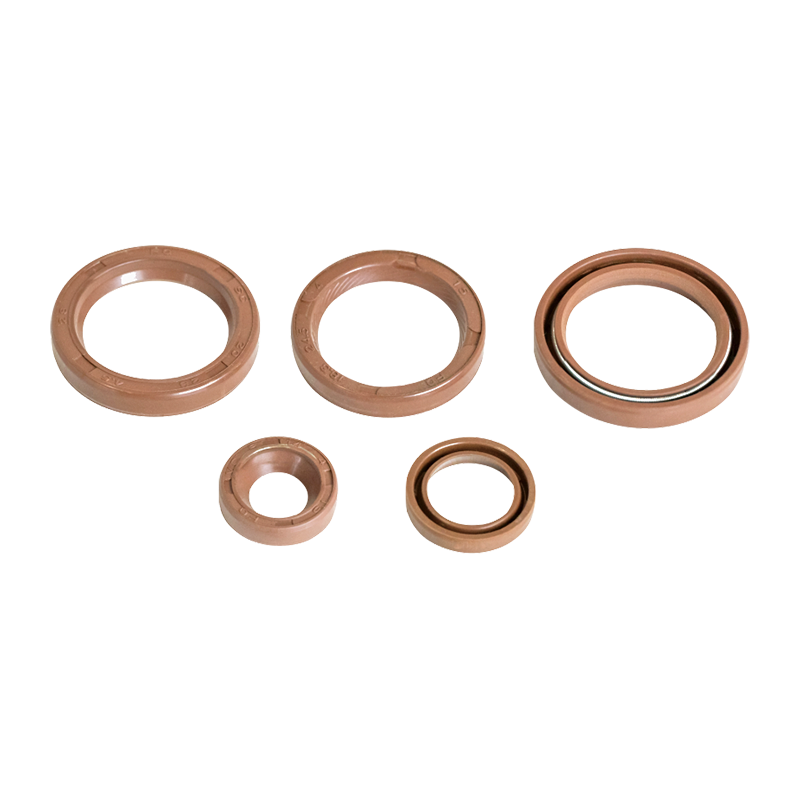

Based on the excellent performance of FKM fluororubber, FKM skeleton oil seals have become the first choice for seals in high temperature and high pressure environments. FKM skeleton oil seals are usually composed of FKM fluororubber sealing lips, metal skeletons and springs. Among them, the FKM fluororubber sealing lips are the key to the sealing effect, while the metal skeletons and springs provide the necessary support and preload.

Under high temperature and high pressure environments, the sealing lips of FKM skeleton oil seals can fit tightly to the surface of the shaft or hole to form an effective sealing gap. Since FKM fluororubber has a low compression permanent deformation rate, the sealing lip can maintain the stability of its shape and size even when working for a long time under high temperature and high pressure, thus ensuring the durability of the sealing effect. In addition, FKM fluororubber also has good chemical corrosion resistance and can resist the erosion of various oils, solvents and chemicals, further enhancing the applicability of FKM skeleton oil seals in high temperature and high pressure environments.

There are many application cases of FKM skeleton oil seals in high temperature and high pressure environments, covering many fields such as automobile manufacturing, aerospace, and petrochemicals. Taking automobile engines as an example, when the engine works under high temperature and high pressure, the leakage of engine oil and fuel has always troubled automobile manufacturers. Traditional sealing materials are often difficult to withstand the high temperature and high pressure environment inside the engine, resulting in oil and fuel leakage, which in turn affects the performance and service life of the engine. After using FKM skeleton oil seals, due to its excellent high temperature resistance and compression deformation performance, it can effectively prevent the leakage of engine oil and fuel and ensure the stable operation of the engine.

In the field of aerospace, FKM skeleton oil seals also play an important role. Aerospace equipment often needs to work in extreme high temperature and high pressure environments, such as the combustion chamber and turbo pump of rocket engines. The seals in these components not only have to withstand the test of high temperature and high pressure, but also face strong vibration and impact. FKM skeleton oil seals, with their excellent high temperature resistance, chemical corrosion resistance and impact resistance, have demonstrated excellent sealing effects under these extreme conditions, providing a strong guarantee for the stable operation of aerospace equipment.

With the continuous advancement of industrial technology and the increasing environmental protection requirements, the requirements for sealing materials are also getting higher and higher. FKM fluororubber skeleton oil seals, with their excellent high temperature resistance, chemical corrosion resistance and compression deformation performance, have demonstrated excellent sealing effects under high temperature and high pressure environments. In the future, with the continuous development of materials science and manufacturing technology, the performance of FKM fluororubber will be further improved, and the application field of FKM skeleton oil seals will be more extensive. Whether in the fields of automobile manufacturing, aerospace or petrochemicals, FKM skeleton oil seals will continue to play their irreplaceable role and contribute more to the innovation and upgrading of the industrial field.

Sray up to date with allour recent products

- Address: No. 6 Yangsha Road, Chengbei Industrial Park, Huilong Town, Qidong City, Jiangsu Province China

- Phone: +86-13906283641+86-18934546679

- Fax: +86-0513-83698022

- Email: [email protected]

English

English русский

русский 中文简体

中文简体