Red silicone O-ring: How to maintain elasticity at extremely low temperatures and protect equipment safety?

Low-temperature elasticity of silicone materials: scientific principles and performance

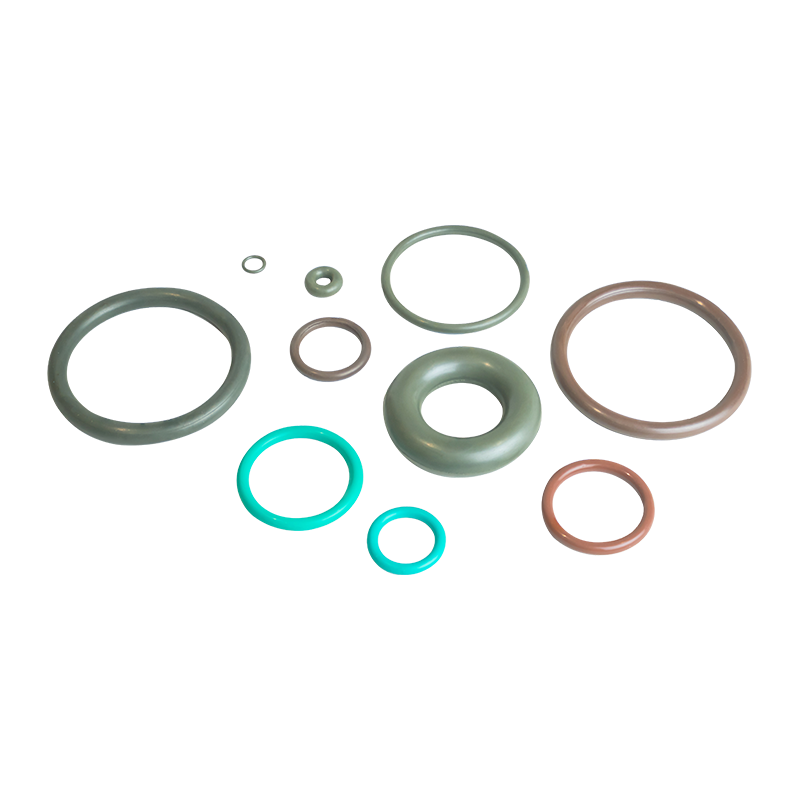

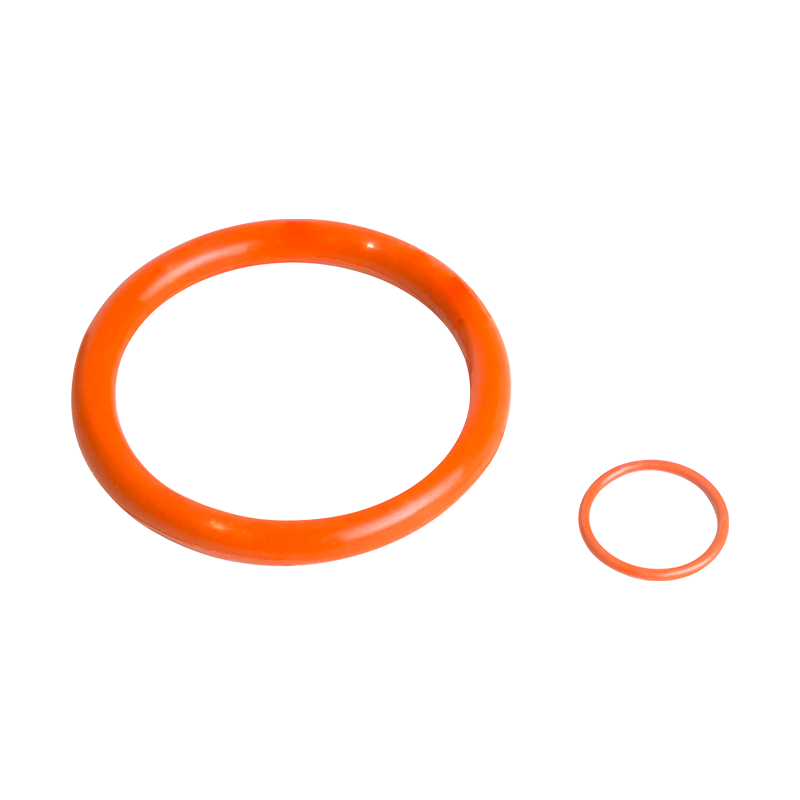

Silicone, as a high-performance synthetic rubber, has shown wide application potential in the field of sealing with its unique physical and chemical properties. Red silicone O-ring, as an important application form of silicone material, not only has all the basic properties of silicone, but also is easy to identify and track due to the eye-catching red mark, which improves the convenience of use in industrial environments.

In low-temperature environments, many materials lose elasticity due to hardening or embrittlement, resulting in sealing failure. However, red silicone O-rings can maintain excellent elasticity under extreme low temperature conditions, which is mainly due to the molecular structure and chemical properties of the silicone material itself.

The silicon-oxygen bond (Si-O) in the silicone molecular chain has a high bond energy, which enables the silicone material to maintain the flexibility of the molecular chain at low temperatures and is not prone to hardening or embrittlement. In addition, the cross-linked structure between silicone molecular chains also provides it with good elastic recovery ability. Even if it is subjected to external forces at low temperatures, it can quickly return to its original shape, thereby maintaining the integrity of the seal.

Experimental data show that red silicone O-rings can still maintain stable elasticity and sealing performance at -60℃ or even lower. This feature enables it to continuously provide reliable sealing protection in equipment operating in cold areas or low-temperature environments, such as polar scientific research equipment, cold chain logistics equipment, low-temperature laboratory instruments, etc., to avoid equipment failure or safety accidents caused by sealing failure.

Production process and quality control: key factors to ensure low-temperature elasticity

The ability of red silicone O-rings to maintain excellent elasticity at low temperatures is not only due to the characteristics of the silicone material itself, but also inseparable from the strict quality control in its production process. From raw material selection, formula design, mold manufacturing to vulcanization molding, quality inspection, each step is carefully planned and strictly controlled to ensure that the final product meets or even exceeds industry standards.

Raw material selection: Use high-purity silicone raw materials to ensure the basic performance of the product. The purity and stability of the raw materials directly affect the low-temperature elasticity and aging resistance of the silicone O-ring.

Formula optimization: By adjusting the cross-linking degree, filler type and content of the silicone, the product's temperature resistance and aging resistance can be further improved. Reasonable formula design can enhance the interaction between silicone molecular chains, thereby improving its elastic recovery ability at low temperatures.

Precision manufacturing: Use high-precision molds and advanced vulcanization molding technology to ensure the dimensional accuracy and surface finish of the O-ring. The accuracy of the mold and the control of the vulcanization molding process directly affect the shape stability and sealing performance of the product.

Strict testing: Through a series of rigorous physical and chemical performance tests, including but not limited to temperature resistance tests, pressure tests, corrosion resistance tests, etc., to ensure that each batch of products can meet the specific needs of customers. In particular, the low-temperature elasticity test can intuitively reflect the sealing performance of silicone O-rings under extreme low temperature conditions.

Application fields and case sharing: Low-temperature value of red silicone O-rings

With its excellent low-temperature elasticity and stable sealing performance, red silicone O-rings have shown a wide range of application value in many fields. The following are some typical application cases that show the unique advantages of red silicone O-rings in low-temperature environments.

Cold chain logistics: In cold chain logistics equipment, such as refrigerated trucks, cold storage doors, etc., red silicone O-rings are used as seals to effectively prevent the leakage of cold air and maintain the stability of the refrigerated environment. Its excellent low-temperature elasticity ensures that it can maintain a tight seal even in extremely cold conditions, reduce energy consumption, and improve the efficiency and safety of cold chain logistics.

Polar scientific research: In polar scientific research equipment, such as scientific research ships and scientific research stations, red silicone O-rings are used as seals of key components, which can maintain stable sealing performance in extremely low temperature environments, ensuring the normal operation of the equipment and accurate data collection. Its aging resistance also ensures that the integrity of the seal can be maintained even after long-term exposure to harsh environments.

Low-temperature laboratories: In low-temperature laboratories, such as low-temperature experimental equipment in the fields of materials science and biomedicine, red silicone O-rings are used as seals to ensure the stability and safety of the experimental environment. Its excellent low-temperature elasticity and corrosion resistance enable the equipment to operate stably for a long time under extremely low temperature conditions, providing reliable protection for scientific research.

Sray up to date with allour recent products

- Address: No. 6 Yangsha Road, Chengbei Industrial Park, Huilong Town, Qidong City, Jiangsu Province China

- Phone: +86-13906283641+86-18934546679

- Fax: +86-0513-83698022

- Email: [email protected]

English

English русский

русский 中文简体

中文简体