VG pipe seals: high-rise building safety guards under exquisite craftsmanship and strict quality control

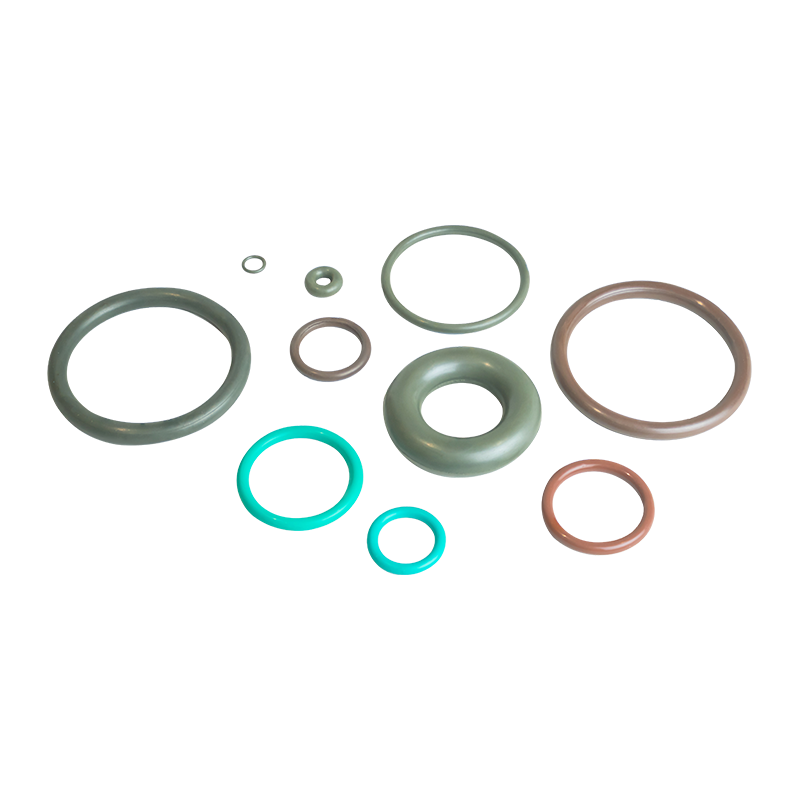

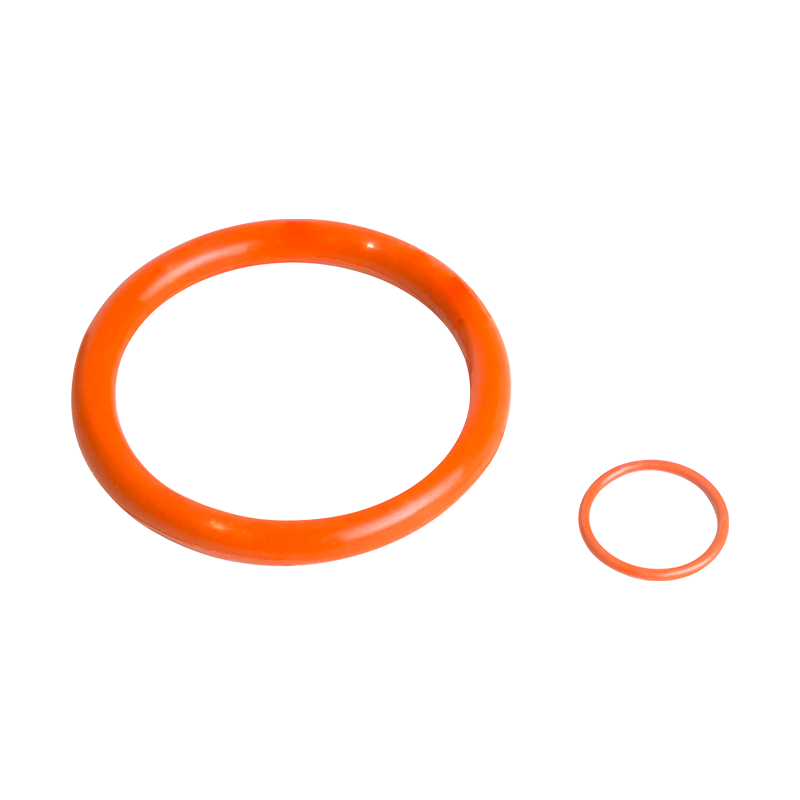

VG pipe seals use vinyl-acrylate rubber (Vamac, referred to as VG) as the main material. This material is known for its excellent heat resistance, oil resistance, chemical resistance and ozone resistance, and is particularly suitable for manufacturing high-performance seals. In high-rise buildings, pipeline systems often need to withstand extremely high pressure and temperature fluctuations. The high strength and stability of VG materials enable VG pipe seals to maintain a stable sealing effect under extreme conditions, effectively prevent fluid leakage, and ensure the safe operation of the pipeline system.

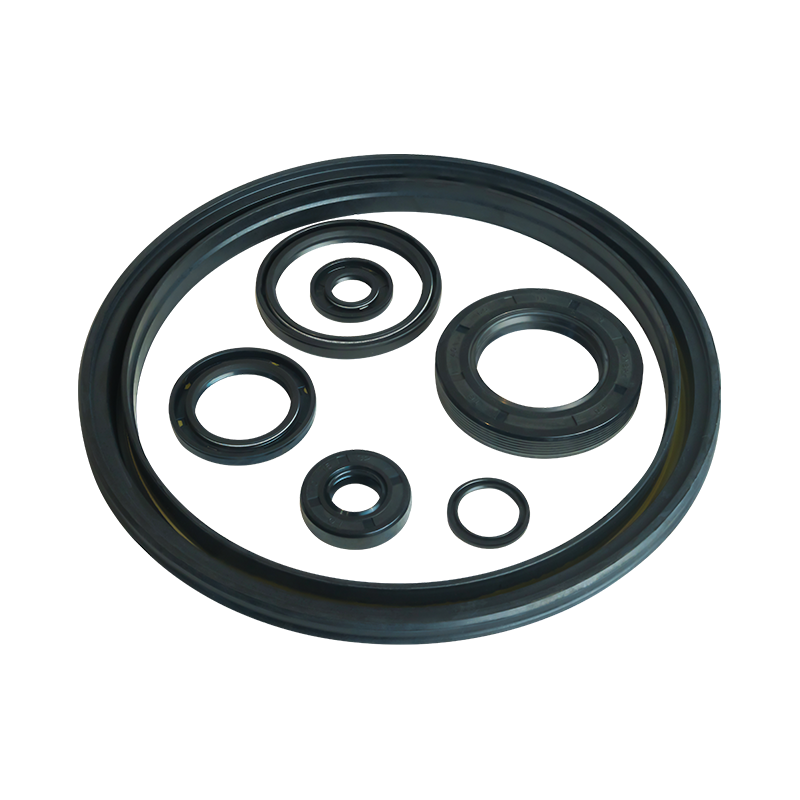

The excellent sealing performance of VG pipe seals is due to its exquisite production process. In the production process, advanced compression molding technology is used, which is a key step to ensure the quality of seals. Compression molding technology precisely controls the size and shape of the mold and presses the VG material under high temperature and high pressure to ensure the dimensional accuracy and surface characteristics of the seal.

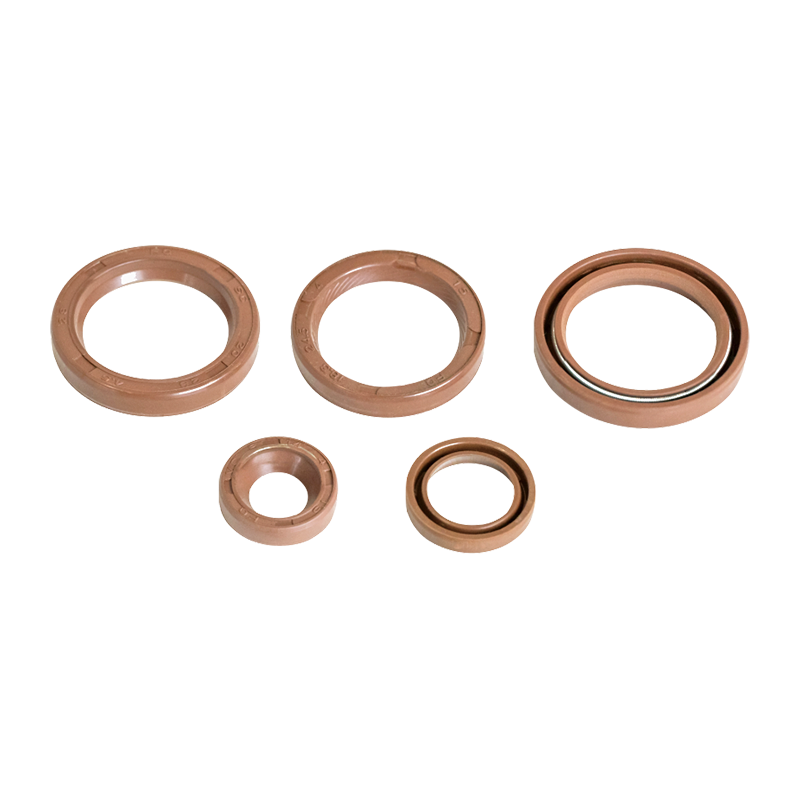

Mold design and manufacturing: The mold is the core of compression molding technology, and its design and manufacturing accuracy directly affect the dimensional accuracy and surface quality of the seal. In the production process of VG pipe seals, the design of the mold fully considers the use environment and performance requirements of the seals, ensuring that the size, shape and tolerance of the mold meet strict standards. At the same time, the manufacture of the mold adopts advanced processing technology and materials to ensure the precision and durability of the mold.

Material selection and pretreatment: The selection and pretreatment of VG materials are crucial to the performance of the seal. During the production process, high-quality VG materials are selected and undergo strict pretreatment, such as drying, mixing, plasticizing, etc., to ensure the uniformity and stability of the materials. These pretreatment steps help to eliminate bubbles and impurities in the material and improve the sealing performance and durability of the seal.

Compression molding: During the compression molding process, the pretreated VG material is placed in the mold and then pressed under high temperature and high pressure. High temperature helps the softening and flow of the material, while high pressure ensures that the material can fully fill every corner of the mold to form a dense seal. By precisely controlling the molding temperature and pressure, the dimensional accuracy and surface characteristics of the seal can be ensured, while improving the sealing performance and durability of the seal.

Post-processing and testing: After compression molding, the seal also needs to undergo a series of post-processing and testing steps to ensure that its quality meets the standards. These steps include deburring, cleaning, drying, etc. to eliminate defects and impurities generated during the molding process. At the same time, the seals need to be tested for air tightness, pressure, etc. to ensure that their sealing performance and durability meet the design requirements.

In addition to exquisite production technology, VG pipe seals also adopt strict quality control measures to ensure that each batch of seals meets strict quality standards. These quality control measures include raw material inspection, production process monitoring, finished product testing and other links.

Raw material inspection: Before the raw materials enter the production line, they need to be strictly inspected and tested to ensure that their quality meets the standards. These inspections and tests include tests on the physical properties, chemical properties, heat resistance, oil resistance and other aspects of the materials.

Production process monitoring: During the production process, advanced monitoring technology and equipment are used to monitor and record each link in the production process in real time. These monitoring data include key parameters such as molding temperature, pressure, time, etc. to ensure the stability and controllability of the production process.

Finished product inspection: After the seal is produced, strict finished product inspection is required. These inspections include appearance inspection, dimensional measurement, air tightness test, pressure test and other aspects to ensure that the quality of the seal meets the design requirements. At the same time, sampling inspection of finished products is also required to verify the stability and reliability of the production process.

In high-rise buildings, VG pipe seals are widely used, covering water supply and drainage systems, HVAC systems, fire protection systems and other fields. Whether it is conveying clean water, hot water, cold water, or handling corrosive fluids, VG pipe seals can ensure the normal operation of the pipeline system with their excellent sealing performance and chemical resistance. At the same time, its good aging resistance and low pressure change performance enable the seal to maintain a stable sealing effect during long-term use, extending the service life of the pipeline system.

Sray up to date with allour recent products

- Address: No. 6 Yangsha Road, Chengbei Industrial Park, Huilong Town, Qidong City, Jiangsu Province China

- Phone: +86-13906283641+86-18934546679

- Fax: +86-0513-83698022

- Email: [email protected]

English

English русский

русский 中文简体

中文简体