How to choose the right oil seal material to ensure long-term stable sealing performance?

To choose the right oil seal material to ensure long-term stable sealing performance in a high temperature environment, the following key factors need to be considered:

Material high temperature resistance:

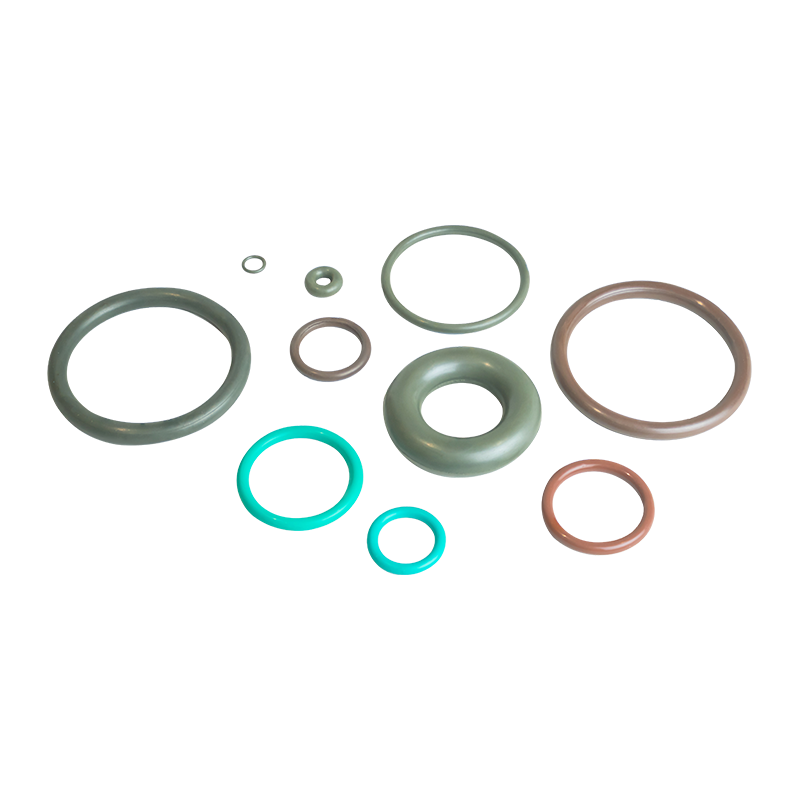

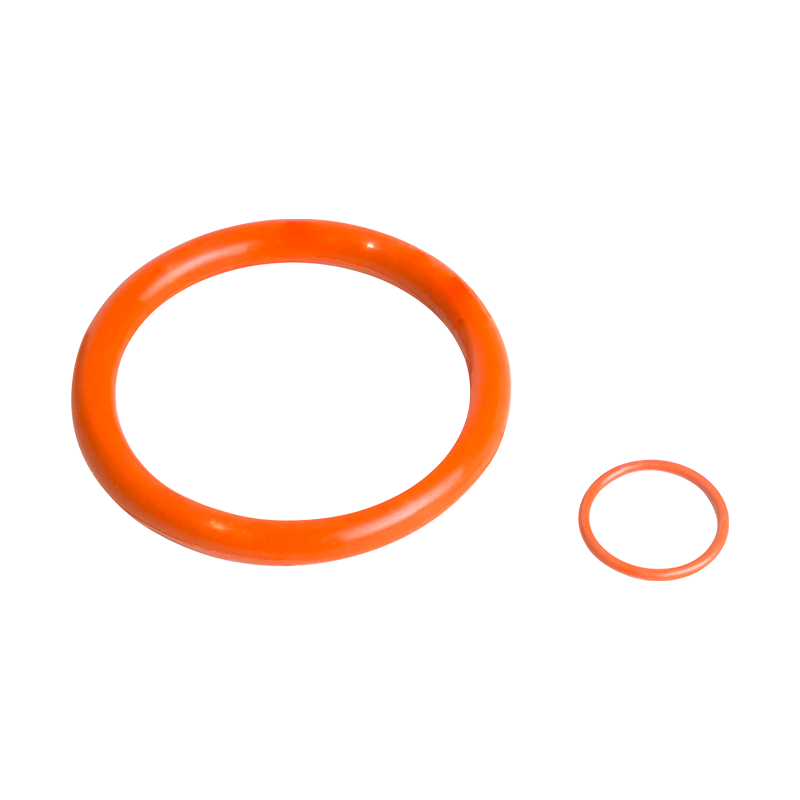

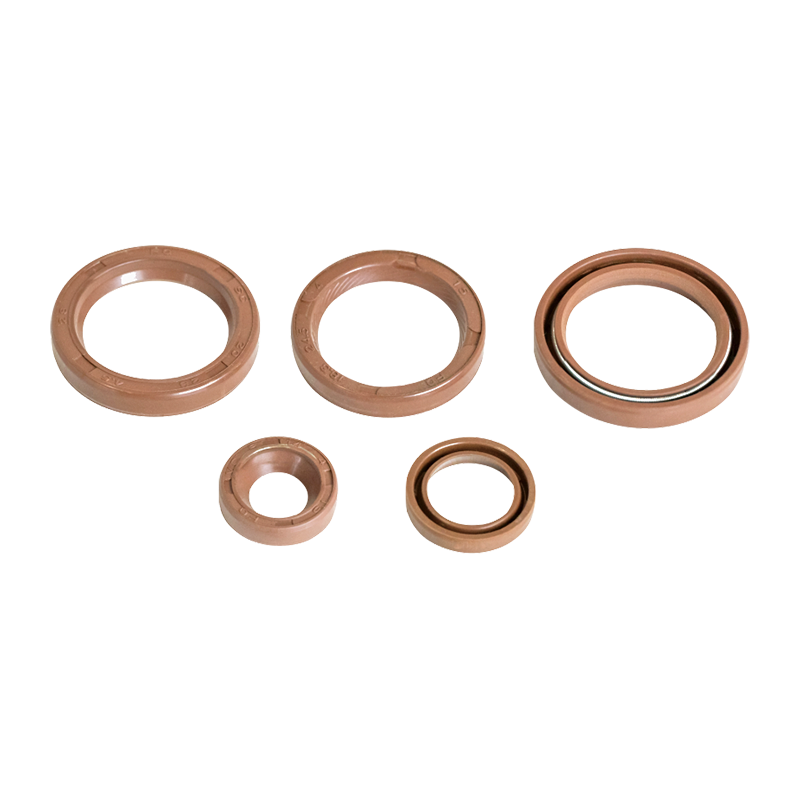

Fluororubber (FKM): has excellent high temperature resistance and can usually withstand a temperature range of 150°C to 250°C. Suitable for applications that need to work in a high temperature environment for a long time.

Silicone rubber (VMQ): can withstand temperatures up to 200°C, while maintaining good elasticity and sealing performance in low temperature environments.

Chemical stability of materials:

In high temperature environments, oil seal materials need to have good chemical stability to prevent material degradation caused by high temperature. It is key to choose materials that will not chemically react or degrade at high temperatures.

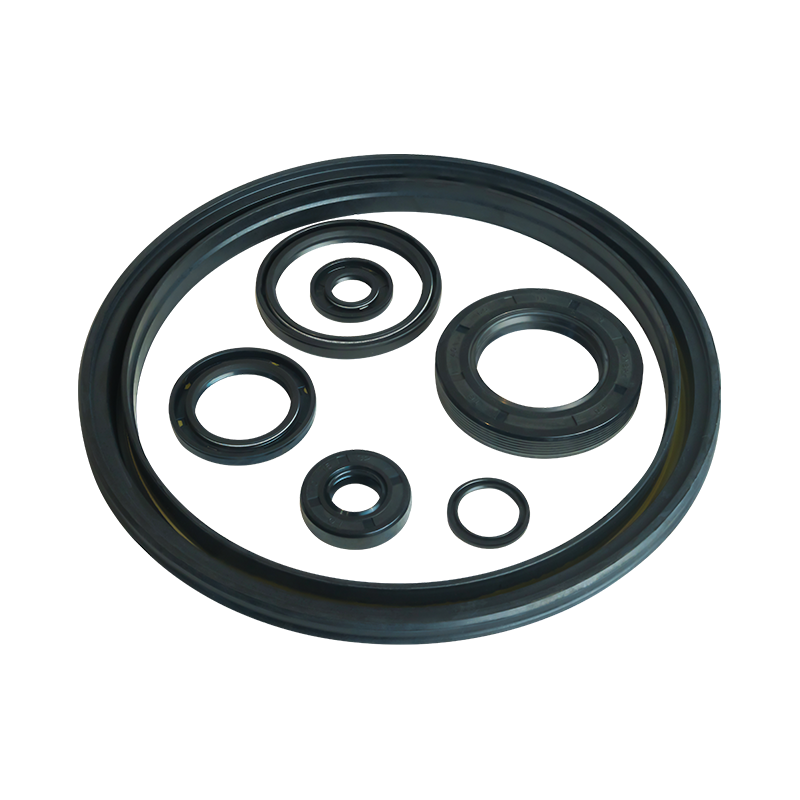

Elasticity and recovery of materials:

Under high temperature conditions, the elasticity of oil seal materials may decrease, so choosing materials that can maintain elasticity even at high temperatures can ensure a continuous sealing effect.

Material anti-aging performance:

High temperature environments will accelerate the aging process of materials, and choosing materials with strong anti-aging performance can extend the service life of oil seals. For example, fluororubber and silicone rubber show good anti-aging properties at high temperatures.

Specific requirements of the application environment:

Select oil seal materials that are adaptable and sufficiently resistant to high temperatures according to the temperature peak and working cycle in the actual application. Possible temperature fluctuations and instantaneous temperature rises also need to be considered.

When selecting oil seal materials suitable for high temperature environments, it is necessary to comprehensively consider the material's high temperature resistance, chemical stability, elastic recovery ability, anti-aging performance, and specific requirements of the application environment. Through these comprehensive factors, it can be ensured that the oil seal can maintain long-term stable sealing performance under high temperature conditions.

Sray up to date with allour recent products

- Address: No. 6 Yangsha Road, Chengbei Industrial Park, Huilong Town, Qidong City, Jiangsu Province China

- Phone: +86-13906283641+86-18934546679

- Fax: +86-0513-83698022

- Email: [email protected]

English

English русский

русский 中文简体

中文简体