High temperature resistant FKM skeleton oil seal: Why is its durability so excellent?

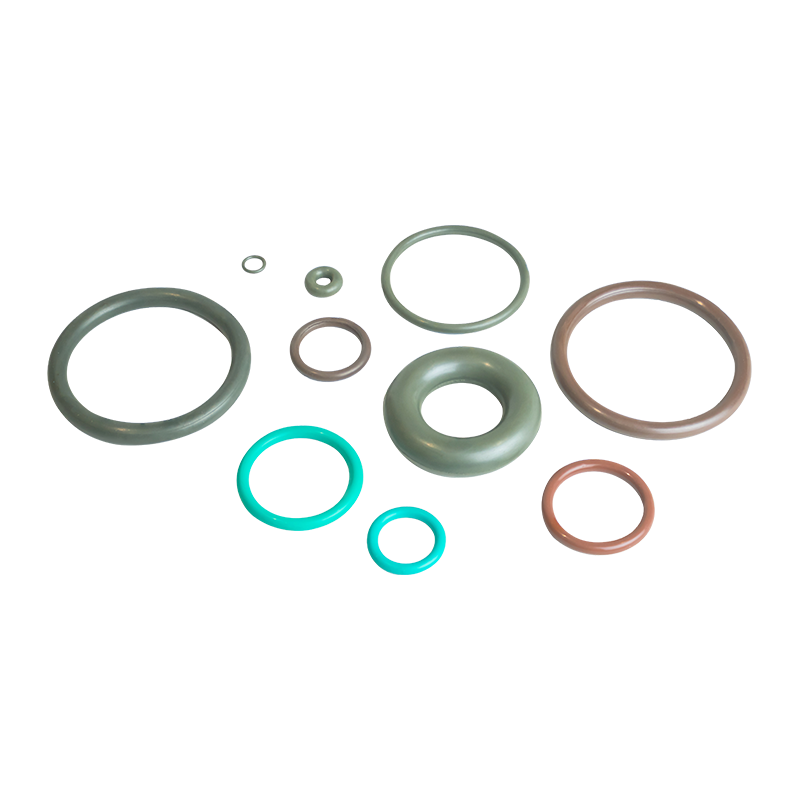

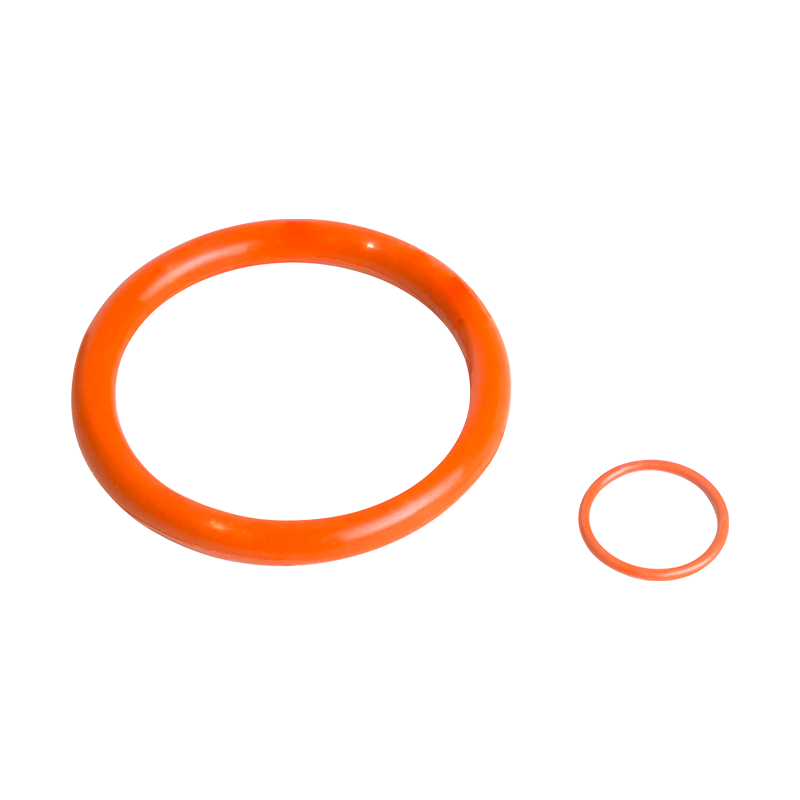

Fluororubber (FKM) is a high-performance elastomer that has demonstrated extraordinary durability in the field of sealing with its unique chemical structure and physical properties. The fluorine atoms in the FKM molecular chain give the material extremely high chemical and thermal stability, enabling it to maintain stable performance under extreme conditions.

Chemical stability:

FKM fluororubber is highly resistant to a variety of chemicals, including oils, fuels, solvents, acids and alkalis. This chemical stability stems from the strong bonding between fluorine atoms and carbon atoms, which makes the FKM molecular chain difficult to be destroyed in chemical media. Therefore, FKM oil seals can maintain stable sealing performance in harsh chemical environments and effectively prevent media leakage.

Thermal stability:

FKM fluororubber has excellent thermal stability and can maintain its physical properties and mechanical strength at high temperatures. Even under extremely high temperature conditions, FKM oil seals will not age or deform, thus ensuring long-term sealing effects. This thermal stability makes it possible to use FKM oil seals in high temperature environments such as engines and gearboxes.

Mechanical strength and wear resistance:

FKM fluororubber has excellent mechanical strength and wear resistance, and can withstand continuous mechanical stress and friction wear. This feature enables FKM oil seals to maintain good sealing effects in long-term operation, reducing equipment failures and downtime caused by seal failure.

In addition to material properties, the structural design of FKM skeleton oil seals is also a key factor in their durability. Reasonable structural design can not only improve the sealing performance of the oil seal, but also enhance its fatigue resistance and wear resistance.

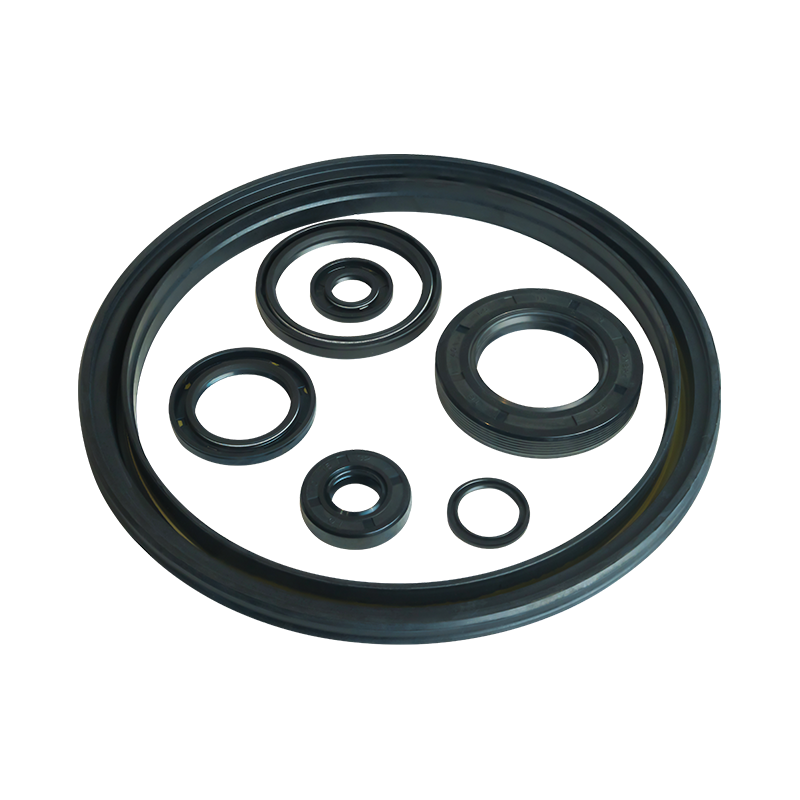

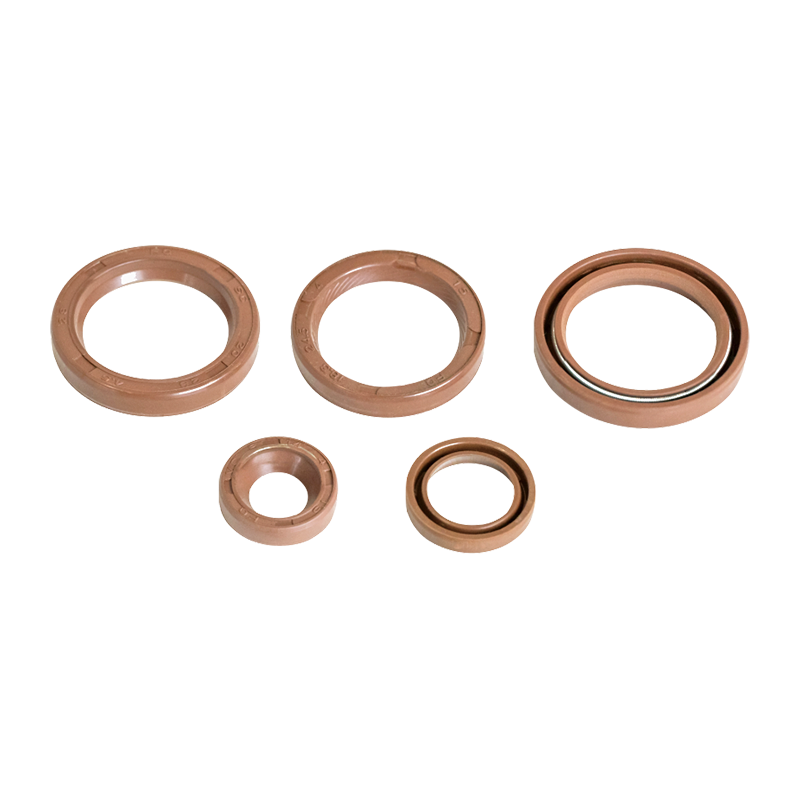

Skeleton design:

The skeleton of FKM skeleton oil seals is usually made of metal or plastic, with high strength and rigidity. The design of the skeleton not only determines the shape and size of the oil seal, but also affects the convenience of its installation and removal. Reasonable skeleton design can ensure that the oil seal will not be damaged during installation, while improving its deformation resistance and fatigue resistance.

Lip design:

The lip is the key part where the oil seal contacts the shaft surface, and its design directly affects the sealing effect and durability of the oil seal. The lip of FKM oil seals usually adopts special geometric shapes and material formulations to improve its sealing performance and wear resistance. For example, the double lip design can further improve the sealing effect of the oil seal while reducing the wear and deformation of the lip.

Spring design:

The spring in the FKM skeleton oil seal is used to provide contact pressure between the lip and the shaft surface to ensure the sealing effect. The design and material selection of the spring have an important impact on the durability of the oil seal. Reasonable spring design can ensure that the lip maintains a stable contact pressure during long-term operation, thereby improving the sealing performance and durability of the oil seal.

The durability of high-temperature resistant FKM skeleton oil seals is not only reflected in laboratory tests, but also fully verified in practical applications. From the automotive industry to aerospace, from chemical processing to oil and gas, FKM oil seals have demonstrated their excellent durability and long life in various fields.

Automotive industry:

In the automotive industry, FKM oil seals are widely used in key parts such as engines, transmissions and fuel systems. These parts are not only subject to high temperatures and high pressures, but also face complex chemical environments. With its excellent chemical resistance and durability, FKM oil seals maintain stable sealing performance under these extreme conditions, ensuring the normal operation of the car.

Aerospace:

In the aerospace field, FKM oil seals are used in hydraulic systems, fuel systems and other key components. These components have extremely high requirements for sealing performance, because any small leaks may lead to serious consequences. With its excellent durability and long life, FKM oil seals play an important role in these key parts, ensuring the safe operation of aerospace equipment.

Chemical processing:

In the chemical processing industry, FKM oil seals are used in equipment that handles corrosive substances. The media in these equipment are often highly corrosive and have extremely high requirements for seals. With its excellent chemical resistance and durability, FKM oil seals maintain stable sealing performance in these harsh environments, ensuring the safety and efficiency of production.

Oil and gas:

In the oil and gas industry, FKM oil seals are used in key components such as drilling equipment, pumps and valves. These components not only face high temperature and high pressure environments, but also face the challenges of corrosive media and mechanical stress. With its excellent durability and long life, FKM oil seals maintain stable sealing performance under these extreme conditions, ensuring the safety of oil and gas extraction and transportation.

Sray up to date with allour recent products

- Address: No. 6 Yangsha Road, Chengbei Industrial Park, Huilong Town, Qidong City, Jiangsu Province China

- Phone: +86-13906283641+86-18934546679

- Fax: +86-0513-83698022

- Email: [email protected]

English

English русский

русский 中文简体

中文简体