Discuss the key influence of groove width on the sealing performance of O-rings

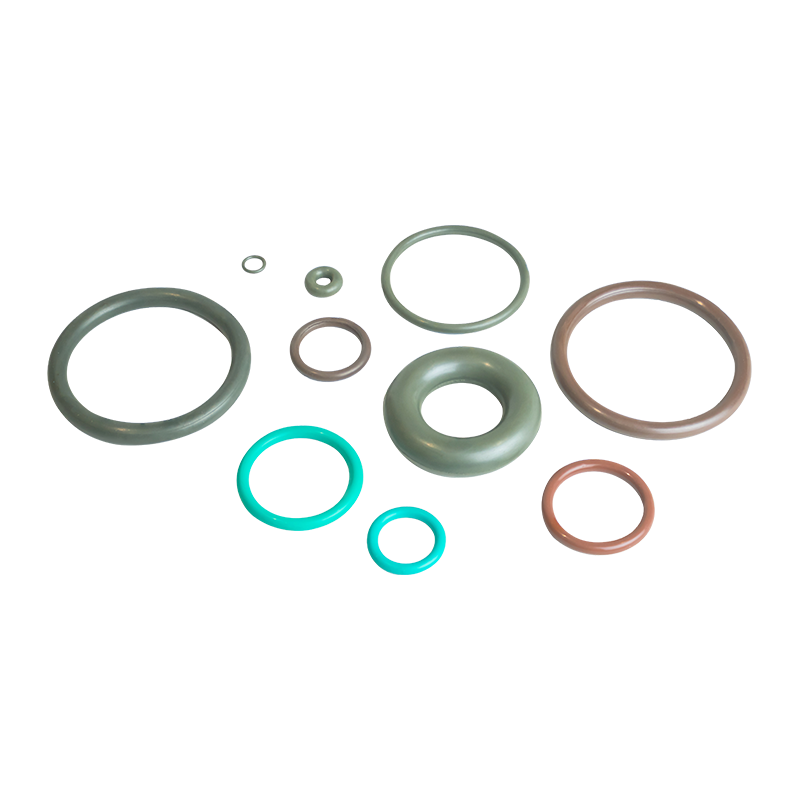

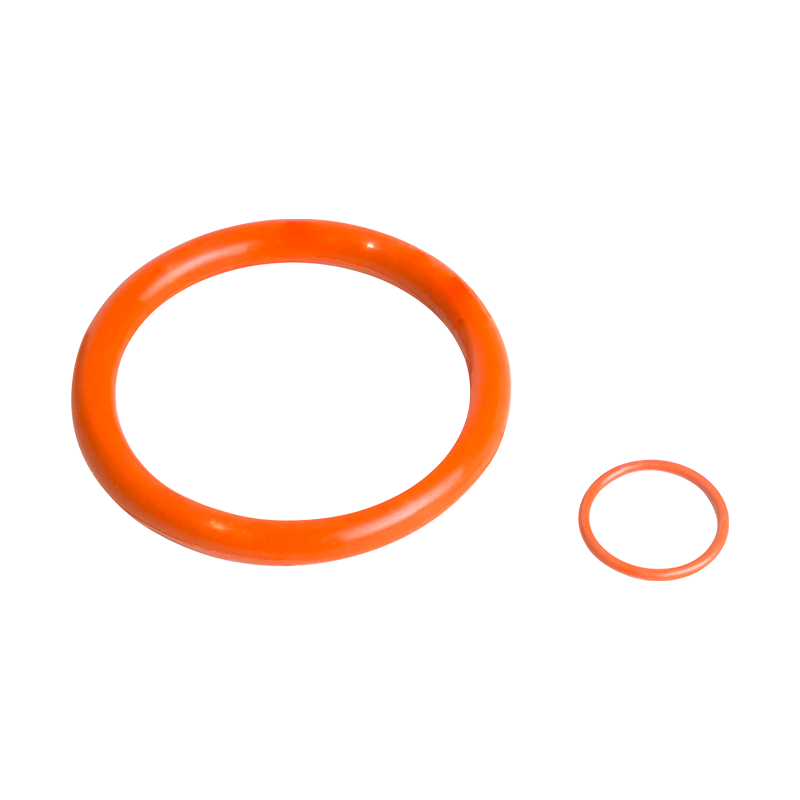

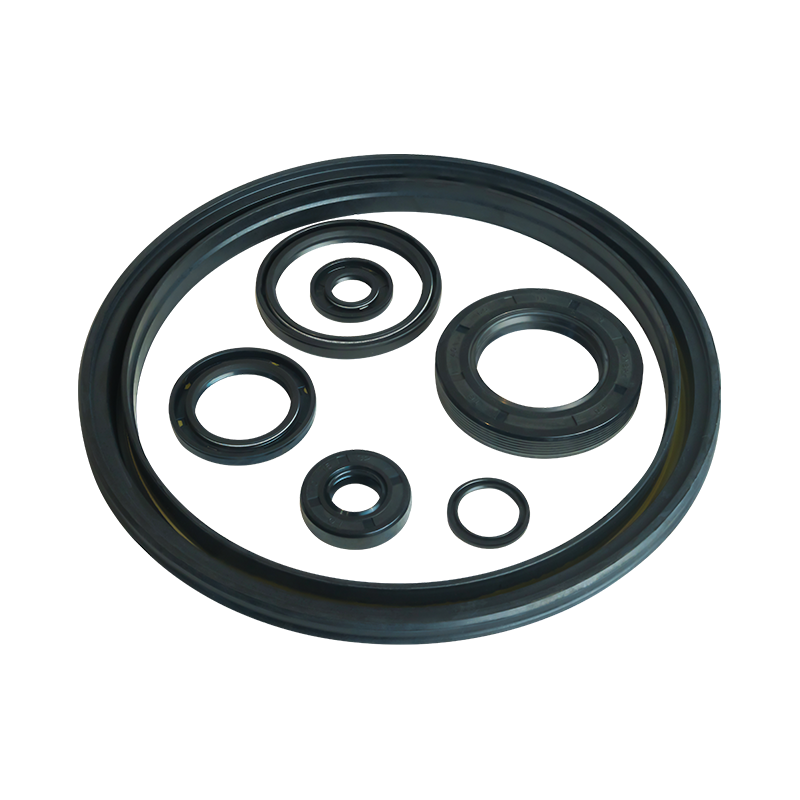

In fluid dynamics, mechanical seals and many industrial applications, O-rings, as a simple and efficient sealing element, play an indispensable role. The stability and reliability of their performance are directly related to the operating efficiency and safety of the entire system. As an important parameter of the O-ring installation environment, the rationality of its design is crucial to ensure the sealing effect of the O-ring.

1. Definition and importance of groove width

Groove width, as the name suggests, refers to the lateral dimension of the groove reserved for the installation of O-rings. This dimension not only determines the position of the O-ring in a static state, but also affects its deformation and sealing effect in dynamic operation. Reasonable groove width design is the first step to ensure the sealing performance of the O-ring.

2. Hidden dangers of too narrow width

When the groove width is designed to be too narrow, the O-ring will be strongly squeezed from the groove wall during installation. This excessive extrusion will not only lead to stress concentration inside the rubber material and accelerate its aging process, but also may prevent the O-ring from fully expanding and completely filling the groove space, thus forming tiny gaps on the sealing interface. These gaps can easily become leakage channels under the action of pressure difference, affecting the sealing performance of the system.

3. Challenges of too wide width

On the contrary, if the groove width is designed to be too wide, although it seems to provide more room for the O-ring to move, it may actually cause new problems. When subjected to system pressure, the overly wide groove allows the O-ring to produce excessive lateral deformation, which may exceed the elastic limit of the rubber material and lead to a decrease in the sealing effect. In addition, excessive deformation may also cause the O-ring to shift or rotate in the groove, further destroying the integrity of the sealing interface and increasing the risk of leakage.

4. Principles for reasonable design of groove width

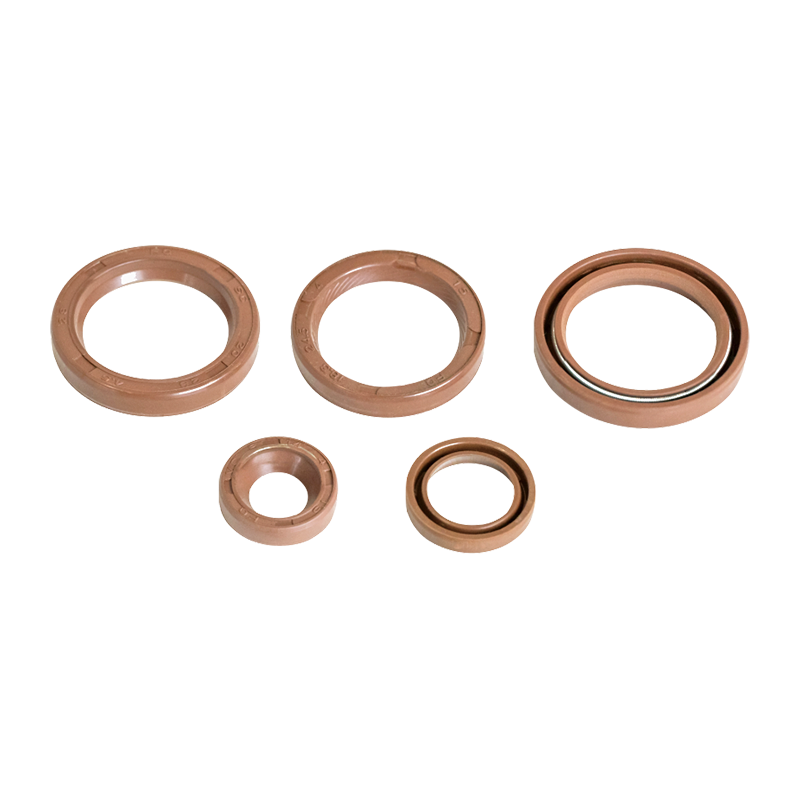

Based on the above analysis, we can draw a conclusion: the design of the groove width must take into account the sealing effect and long-term stability of the O-ring. Generally speaking, the groove width should be slightly larger than 1.3 times the cross-sectional diameter of the O-ring, which is a more reasonable ratio verified by practice. Such a design can not only ensure that the O-ring will not be over-extruded during installation, but also provide sufficient deformation space to form an effective seal during operation.

At the same time, it should also be noted that the design of the groove width should also take into account other factors, such as the nature of the medium, working pressure, temperature conditions, etc. Different working environments have different requirements for O-rings and grooves. Therefore, in practical applications, it is necessary to flexibly adjust and optimize according to specific circumstances.

As an important factor affecting the sealing performance of the O-ring, the rationality of its design is directly related to the sealing effect and long-term stability of the system. Therefore, when designing the groove, the comprehensive influence of various factors must be fully considered to ensure that the O-ring can maintain good sealing performance under various working conditions. Only in this way can we give full play to the advantages of the O-ring as an efficient sealing element and provide reliable protection for industrial production and equipment operation.

Sray up to date with allour recent products

- Address: No. 6 Yangsha Road, Chengbei Industrial Park, Huilong Town, Qidong City, Jiangsu Province China

- Phone: +86-13906283641+86-18934546679

- Fax: +86-0513-83698022

- Email: [email protected]

English

English русский

русский 中文简体

中文简体