A leap forward in the manufacturing process of pipe rubber seals: Isn’t this a solid backing for the safety of the pipe system?

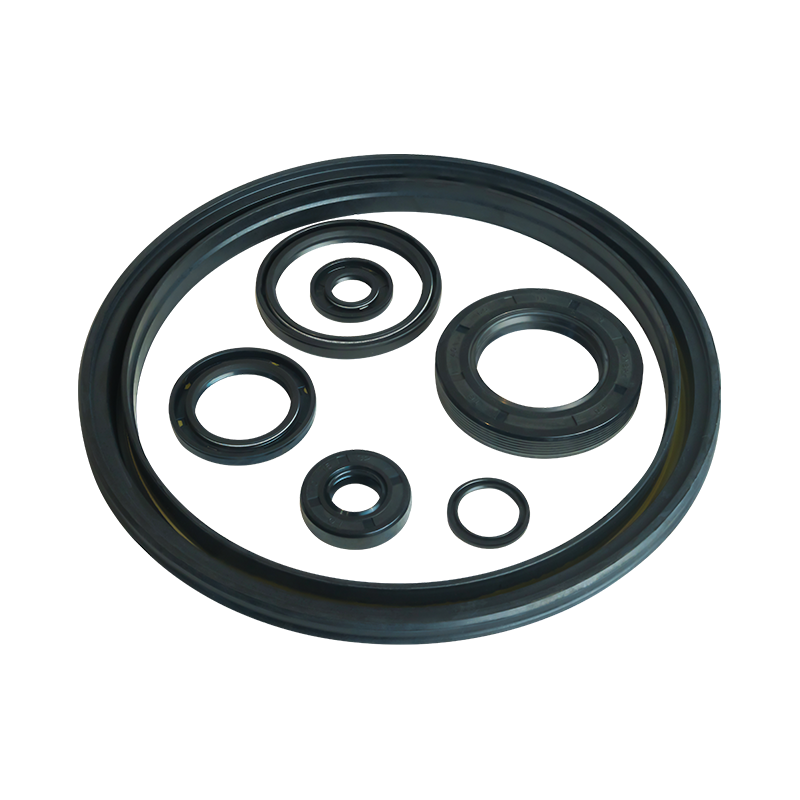

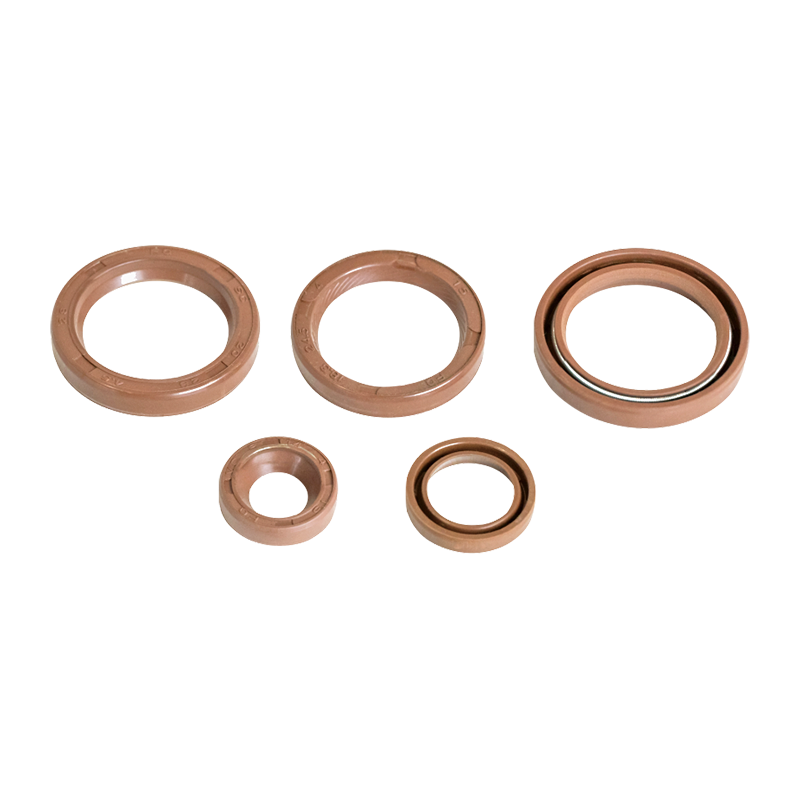

In modern industry and infrastructure, pipeline systems play a vital role. As the core component of pipeline connection, breakthroughs in the manufacturing process of rubber sealing rings are directly related to the safety, reliability and operating efficiency of the pipeline system.

Traditionally, the manufacturing of pipe rubber seals mainly relies on manual operation and simple mechanical equipment. This production method has many limitations, such as low production efficiency, unstable product quality, and high labor costs. Especially when facing sealing rings with complex shapes and high precision requirements, traditional processes are often difficult to cope with, resulting in products that are difficult to meet market demand.

In order to overcome the limitations of traditional processes and improve the production efficiency and product quality of rubber sealing rings, the manufacturing process has undergone several major breakthroughs. With the advent of the Industrial 4.0 era, automated production lines have been widely used in the manufacture of rubber sealing rings. These production lines integrate advanced robotic arms, intelligent sensors, control systems and other high-tech equipment to achieve full automation from raw material delivery to finished product packaging. The introduction of automated production lines not only greatly improves production efficiency, but also significantly reduces labor costs, while reducing the impact of human factors on product quality.

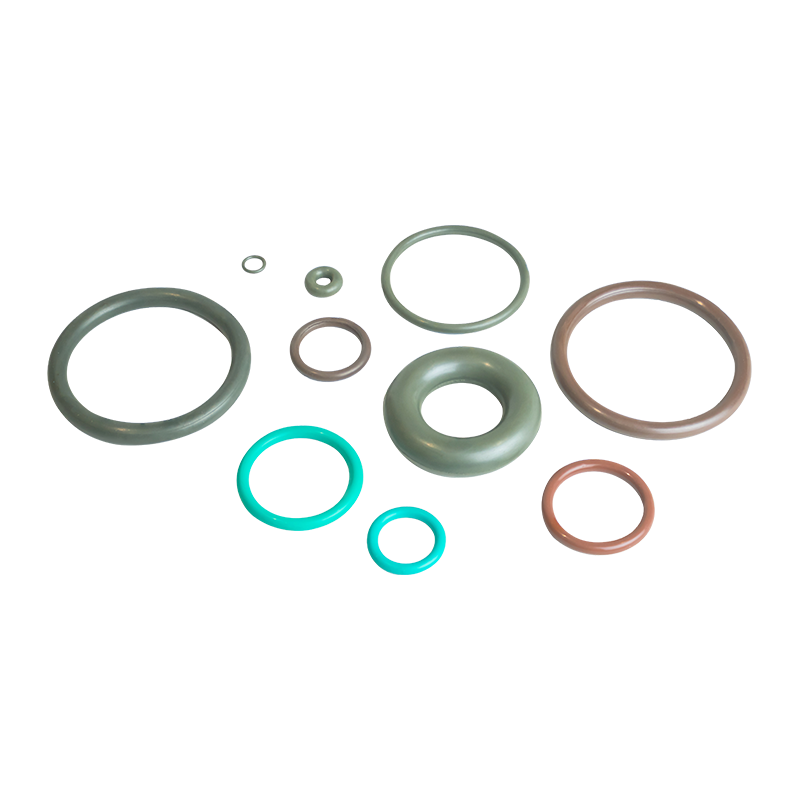

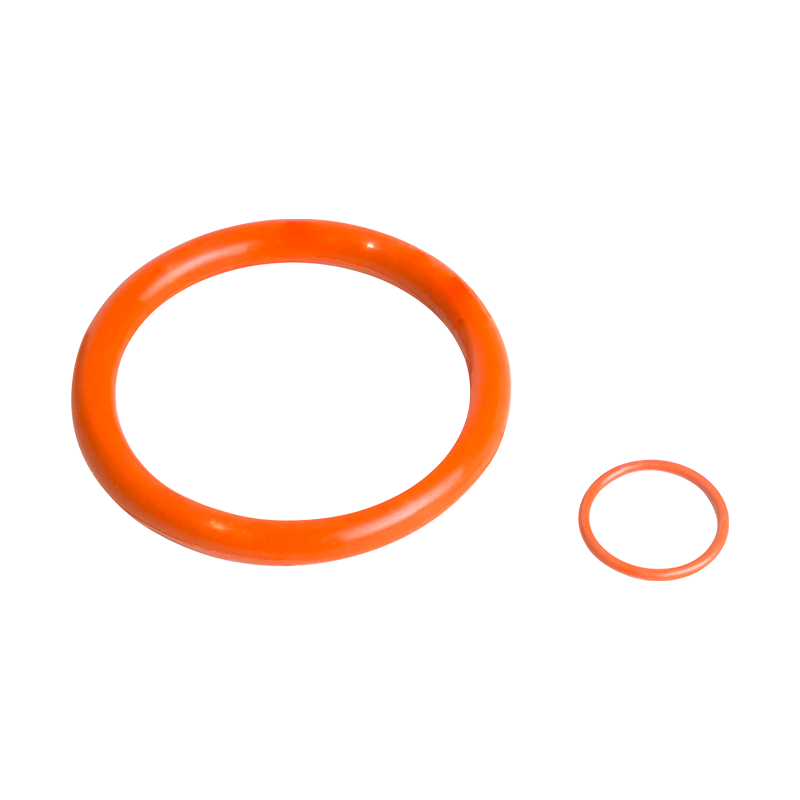

Injection molding is one of the core processes in the manufacture of pipe rubber seals. With the continuous development of precision injection molding technology, today's injection molding machines can accurately control parameters such as injection pressure, temperature, speed, etc., to ensure that the rubber material flows evenly and is fully filled in the mold. This technology makes the produced sealing rings precise in size, complex in shape and high in surface quality, greatly improving the sealing performance and durability of the product.

Vulcanization is a key link in the manufacturing process of pipe rubber seal. Traditional vulcanization processes have problems such as long vulcanization time, high energy consumption, and unstable product quality. Modern vulcanization processes effectively shorten the vulcanization time, reduce energy consumption, and improve the vulcanization uniformity and physical properties of products by adopting advanced vulcanization equipment and process parameter optimization technologies, such as high-temperature rapid vulcanization and segmented vulcanization.

Intelligent quality control also plays an important role in the breakthrough of manufacturing processes. Modern rubber sealing ring manufacturers have achieved real-time monitoring and data analysis of each link in the production process by introducing intelligent detection systems and big data analysis technologies. These systems can promptly detect and handle abnormal situations in production to ensure the consistency and stability of product quality. At the same time, big data analysis also provides valuable production data support for enterprises, which helps enterprises optimize production processes and improve production efficiency.

In the breakthrough of manufacturing technology, environmental protection and sustainable development are also important aspects that cannot be ignored. Modern rubber sealing ring manufacturers focus on using environmentally friendly materials and production processes to reduce the impact on the environment.

The breakthrough of pipeline rubber sealing ring manufacturing technology is multi-faceted and multi-level. In the future, with the continuous advancement of science and technology and the continuous changes in market demand, the rubber sealing ring manufacturing process will usher in more innovations and breakthroughs, providing a more solid guarantee for the safe and reliable operation of the pipeline system.

Sray up to date with allour recent products

- Address: No. 6 Yangsha Road, Chengbei Industrial Park, Huilong Town, Qidong City, Jiangsu Province China

- Phone: +86-13906283641+86-18934546679

- Fax: +86-0513-83698022

- Email: [email protected]

English

English русский

русский 中文简体

中文简体